Mar 24, 2025 |

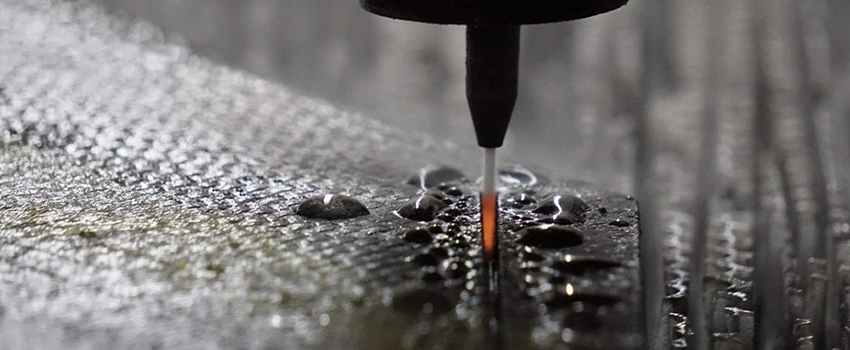

Waterjet Cutting Machine

Waterjet Cutting or Cold Cutting Process is an advanced manufacturing process that utilizes high-pressure jets of water to cut and shape materials with precision. In this process, water is pressurized up to 392 MPa (megapascals) using specialized pumps. The pressurized water is then directed through a small, fine nozzle, where it accelerates to supersonic speeds—often exceeding three times the speed of sound. This results in a powerful, concentrated water stream capable of cutting through a variety of materials, including metals, stone, glass, plastics, and ceramics.

The key advantage of water jet cutting is its ability to make clean, accurate cuts without generating heat, reducing the risk of thermal distortion or material degradation. This makes it an ideal choice for cutting heat-sensitive materials. Additionally, the process is versatile, offering precise cuts in complex shapes and patterns, all without the need for a heat-affected zone or post-processing.

Water jet cutting is highly effective in industries ranging from aerospace to automotive, construction, and art, offering a cost-effective and environmentally friendly alternative to traditional cutting methods. The combination of speed, precision, and minimal material waste makes it an essential tool in modern manufacturing processes.

Advanced Waterjet Technology is a flexible and precise way to cut, shape, and design materials using high-pressure water. It can be done with or without abrasives, depending on the material. For softer materials, plain water works fine, but for harder materials like metals and stone, an abrasive like garnet is added to the water to make cutting easier.

The process starts with a high-pressure pump that pushes water up to 392 MPa (megapascals), which is about 55,000 psi. This pressurized water is forced through a small nozzle, turning it into a fast and focused stream that can cut through many different materials. If abrasives are used, the water stream also speeds up the particles, and these particles help erode and cut the material, creating clean and accurate cuts.

Water jet cutting has many benefits compared to other cutting methods like plasma or laser cutting. One big advantage is that it can cut complex shapes very accurately without generating heat. Plasma and laser cutting create heat, which can change the material or damage delicate surfaces. Water jet cutting doesn’t use heat, so it keeps the material intact. Also, Waterjet Systems leaves clean edges, so there is little or no need for extra finishing work. This saves time and money, making water jet cutting a highly efficient and reliable method for many industries.

A waterjet nozzle is an important part of the water jet cutting process. It focuses the high-pressure water stream onto the material being cut. The main job of the nozzle is to control the water flow precisely, so the cut is accurate and effective. The width of the water stream can change depending on the material and how thick it is, so choosing the right nozzle is important for the best results.

Inside the nozzle is a small hole, called a jewel orifice, usually made from strong materials like sapphire or ruby. This hole helps the water stream exit smoothly, with less friction and more accuracy. The jewel material also helps the nozzle last longer. By using the right nozzle for each material, manufacturers can make clean, precise cuts more efficiently.

Waterjet cutting is one of the most important tools in manufacturing because it’s flexible, precise, and can work with many different materials. Unlike methods like lasers or plasma, waterjet cutting uses high-pressure water, which prevents heat from damaging the material. This makes it perfect for cutting sensitive materials like metals, plastics, glass, and stone, while keeping the material's quality intact.

One of the main benefits of Waterjet Solutions is its ability to make very accurate and detailed cuts. It can handle complex shapes and tight measurements that other methods might struggle with. This precision is especially useful in industries like aerospace, automotive, and medical devices, where quality is critical.

Waterjet cutting is also environmentally friendly because it creates very little waste and doesn’t use harmful chemicals. It’s also cost-effective and efficient, as it eliminates the need for extra steps like cleaning up rough edges. The ability to cut thick materials without causing heat damage makes waterjet cutting a valuable and reliable tool in modern manufacturing.

Waterjet cutting is highly effective for cutting a wide range of metals, including steel, aluminum, brass, and titanium. The key advantage is that it does not produce heat, preventing thermal distortion or altering the metal’s properties. This is especially important for metals that are sensitive to heat, such as thin sheets of aluminum or alloys. Waterjets can cut through both thin and thick metals with extreme precision, making them ideal for industries like aerospace, automotive, and manufacturing. Whether it's for intricate designs or simple straight cuts, waterjet cutting ensures clean edges with minimal burr formation, reducing the need for additional post-processing.

Waterjet Machine is an excellent choice for cutting various types of plastics, including acrylic, polycarbonate, PVC, and polyethylene. Since plastic can be sensitive to heat, traditional cutting methods can cause warping or melting. Waterjet cutting avoids this issue because it uses cold water, ensuring the plastic retains its shape and integrity. The process can handle intricate designs and sharp corners without causing cracking, making it ideal for applications in the automotive, packaging, and electronics industries. Moreover, the precision and smooth finish provided by waterjets often require minimal finishing work.

Advanced Waterjet Technology is particularly valuable for cutting composite materials, such as fiberglass, carbon fiber, and laminated materials. These materials are often tough and resistant to conventional cutting methods, but waterjets can easily cut through them without causing delamination or fiber pullout, which is common with other techniques. The process allows for intricate, accurate cuts that don’t damage the composite’s layers or structure. Waterjet cutting is widely used in industries such as aerospace, construction, and marine applications, where composites are often used for their strength-to-weight ratio and durability.

Waterjet cutting is an ideal method for cutting rubber, as it can create smooth, clean edges without generating heat or causing distortion. Rubber, especially thicker materials, can be challenging to cut with traditional methods, but waterjets can handle both thin and thick rubber sheets with ease. The high-pressure water stream is particularly effective at cutting intricate shapes and designs needed for seals, gaskets, and other rubber components. The process allows for precise cuts, even in complex patterns, and eliminates the risk of material warping, ensuring high-quality, reliable products for industries like automotive and manufacturing.

Waterjet cutting is widely used to cut natural stone materials, including granite, marble, and limestone. Stone is typically difficult to cut with standard tools due to its hardness, but waterjet technology offers a solution by using a high-pressure stream of water, often with abrasives, to slice through stone with ease. This method allows for intricate designs, such as decorative stonework, countertops, and architectural features, while maintaining the stone's natural appearance. Additionally, since waterjet cutting doesn't generate heat, the stone's color and texture remain unaffected, making it ideal for applications where the aesthetics of the material are important.

Waterjet cutting is an effective method for cutting ceramic, porcelain, and glass tiles. Traditional tile cutting methods can result in chips, cracks, or uneven edges, but waterjets provide a smooth, precise cut with minimal waste. This technique is perfect for creating intricate designs or complex shapes needed for mosaics or custom tile work. The waterjet’s ability to cut without heat means the tile won’t crack, and it maintains its color and texture. It’s commonly used in the construction and interior design industries for creating custom patterns, backsplash designs, or floor and wall tiles that require a high level of precision.

Waterjet Solutions is widely used for cutting glass, offering precise, smooth edges without the risk of cracking or breaking that can occur with traditional cutting methods. The process is particularly effective for cutting delicate or laminated glass, such as windows, mirrors, and glass panels for displays. Since there is no heat involved, the structural integrity and clarity of the glass are maintained. Waterjet cutting can also handle intricate designs, making it a preferred method for decorative glasswork. It is commonly used in architecture, automotive, and the glass industry, where both precision and minimal waste are essential.

Waterjet Systems is an ideal method for cutting foam materials, whether they are soft foams used in bedding or cushions or denser, more rigid foams used in packaging or insulation. The ability to cut foam with precision allows for intricate designs and shapes that are often required in industries like packaging, automotive, and furniture manufacturing. The waterjet process does not generate heat, which means the foam won’t melt or become damaged, preserving its structure and softness. Additionally, waterjet cutting is highly efficient, providing clean edges with minimal waste, making it a cost-effective solution.

Waterjet cutting is a popular choice for cutting leather due to its precision and ability to handle intricate designs. Leather can be tough to cut with traditional methods, but waterjets can slice through it smoothly without causing fraying or damage. This makes it ideal for creating custom leather products, such as belts, shoes, bags, and upholstery. The cold water process ensures that the leather’s texture and quality remain intact, and the ability to cut complex shapes without the need for additional finishing steps makes waterjet cutting a reliable and efficient solution for the leather industry.

Water Jet Cutting is an effective technique for cutting paper and cardboard materials. Since the process doesn’t involve heat, it prevents paper from burning or curling, ensuring clean, precise cuts. Waterjet cutting is capable of handling large volumes of paper and can create intricate designs and detailed patterns for packaging, art, and commercial printing. It is ideal for industries where accuracy and fast production times are important. Whether it’s cutting individual sheets of paper or designing complex layers for custom packaging, waterjet cutting ensures high-quality results while minimizing material waste.

Waterjet cutting is increasingly used for cutting wood, especially when intricate designs or high precision is required. Waterjets can cut through wood without generating heat, which prevents warping, burning, or discoloration that can happen with other cutting methods. The process can handle both softwoods and hardwoods, making it versatile for use in industries such as furniture making, cabinetry, and art. Whether it’s for custom wood carvings or precise cuts for furniture components, waterjet cutting ensures smooth, clean edges and minimal post-processing, improving both quality and efficiency in wood production.

Choosing Accurate cutting services is important to get the best results for your project. With the right provider, you can be sure that the work will meet your exact needs. Experienced cutting services bring years of skill and knowledge to ensure the job is done correctly from the start. Many of these services use waterjet cutting, a method known for being precise, flexible, and able to cut through different materials without causing heat damage.

A skilled team in Waterjet Cutting can handle even the most detailed designs, making sure everything is cut accurately. This reduces the need for extra work or changes after the job is done.

Additionally, picking a cutting service with a strong history of successful projects means they understand the needs of different industries and can provide consistent, high-quality results. The right team will also use the latest technology, making the cutting process more efficient and minimizing waste.

In the end, by choosing a trusted cutting service with an experienced team that focuses on quality, you can be sure your project will meet high standards, saving both time and money in the process.

In conclusion, Water Jet is an important and effective method for cutting materials precisely in many industries. It is very flexible, allowing it to cut materials like metals, plastics, glass, and composites without causing heat damage. This makes it perfect for materials that can’t handle the heat used in other cutting methods. Waterjet cutting also creates clean and accurate cuts, which means there is less need for extra work afterward, making it cost-effective. By choosing a trustworthy cutting service, especially one with experience in waterjet cutting, businesses can make sure their projects are done with high precision and efficiency. With the right team and tools, waterjet cutting provides consistent, high-quality results, saving time, money, and resources, while meeting the high standards needed in industries like aerospace, automotive, and manufacturing. Waterjet cutting remains a valuable and reliable tool in modern manufacturing, offering quality and precision.

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.