In the field of modern manufacturing and precision engineering, waterjet cutting technology has emerged as a highly flexible and efficient method. Using high-pressure jets of water mixed with an abrasive, Advanced waterjet technology allows for precise cutting of a wide range of materials, from metals to composites and stone. This capability makes it the preferred choice in various industries.

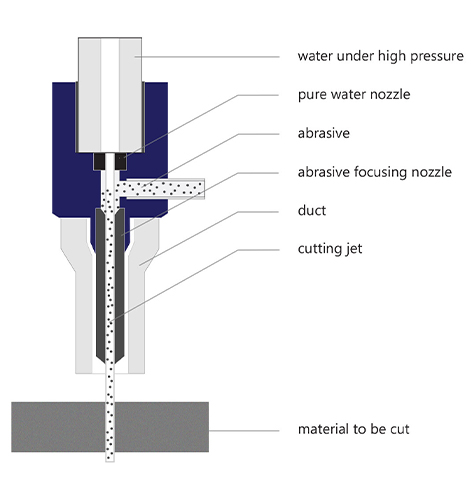

Waterjet cutting is an adaptable and expert method used to cut a variety of materials, from metal and glass to stone and plastics. The waterjet cutting process involves using a high-pressure stream of water, often mixed with abrasive particles, to slice through materials with precision. Water is pressurized to extremely high levels. This pressurized water is then directed through a narrow nozzle, creating a thin, powerful jet. When abrasive materials like garnet are added, the cutting power increases significantly, allowing it to tackle harder materials.

One of the main advantages of waterjet cutting is that it produces minimal heat, which helps prevent warping or damage to the material being cut. This makes it particularly useful for sensitive materials and applications where maintaining structural integrity is crucial. Water Jet Cutting is also highly customizable. It can create intricate shapes and designs, making it popular in industries like aerospace, automotive, and architecture. Additionally, because it doesn’t produce toxic fumes or waste, it’s considered an environmentally friendly option. Water Jet Application delivers every cut clean and precise across a wide range of applications.

Waterjet cutting machines work on the principle of erosion, where a stream of water (usually pressurised between 20,000 and 100,000 pounds per square inch) is advanced through a small nozzle at extremely high speeds. To increase cutting efficiency, abrasives such as garnet are often added to the water stream, which significantly increases its cutting power. This method enables waterjets to slice through material with remarkable precision, leaving smooth edges that often require no further finishing.

Waterjet cutting machines work on the principle of erosion, where a stream of water (usually pressurised between 20,000 and 100,000 pounds per square inch) is advanced through a small nozzle at extremely high speeds. To increase cutting efficiency, abrasives such as garnet are often added to the water stream, which significantly increases its cutting power. This method enables waterjets to slice through material with remarkable precision, leaving smooth edges that often require no further finishing.

1. Precision and Intricacy: water jet cutter is known for its ability to cut complex shapes with tight tolerances, making it suitable for detailed designs and patterns.

2. No heat-affected zone: Unlike thermal cutting methods such as laser or plasma cutting, waterjet technology does not produce a heat-affected zone (HAZ), which minimises material distortion or changes due to heat.

3. Environmentally friendly: A cold cutting process that uses water and abrasives, the waterjet cutter machine produces minimal waste and emits no harmful gases or by-products.

4. Cost-Effective: While the initial setup costs may be higher than traditional cutting methods, the overall cost-effectiveness of waterjet cutting results from reduced material waste, lower energy consumption, and fewer secondary operations.

5. Versatility: From thin foil to thick blocks, waterjet cutting adapts to a wide range of material thicknesses and types without requiring tool changes or adjustments.

waterjet cutter Machine offers a wide range of applications across various industries. Its versatility, precision, and efficiency make it a valuable tool for cutting, shaping, cleaning, and preparing materials. As technology continues to advance, we can expect further advancements and innovations in water jet technology, opening up new possibilities for its use across industries.

Advances in waterjet technology are expanding the limits of what can be achieved. Improved accuracy, faster cutting speed and collaboration with robotics are among the areas where continuous research and development seeks to increase effectiveness and expand application opportunities.

Waterjet cutting services present an appealing choice for industries that need precise, adaptable, and environmentally friendly cutting methods. As technology continues to advance, its influence on manufacturing and design is poised to expand, continuing to redefine what can be achieved in terms of precision engineering and material processing.

At Accurate Cutting Services, we stand out for our extensive experience and commitment to excellence in the field of precision cutting. With years of industry expertise and state-of-the-art technology, including advanced Water Jet Cutter machine, we offer unparalleled capabilities to meet diverse cutting needs with precision and efficiency.

Years of Experience: With a proven track record spanning many years, we bring deep knowledge and expertise to every project. Our experience ensures that we understand the nuances of various materials and applications, delivering consistently high-quality results.

Advanced Technology: We invest in cutting-edge Water Jet Cutter equipped with the latest technology. These machines allow us to achieve intricate cuts with precision, catering to complex designs and specifications across a wide range of materials.

Skilled Expertise: Our team comprises highly skilled professionals who are experts in their field. They possess the technical proficiency and creativity needed to handle challenging projects effectively, ensuring optimal outcomes for our clients.

Proven Success: Over the years, we have successfully completed numerous projects using our advanced Water Jet Cutting machine. Our portfolio showcases our ability to deliver on diverse requirements, from industrial components to artistic creations.

Choosing Accurate Cutting Services means partnering with a trusted provider known for superior cutting solutions backed by years of experience, advanced technology, and skilled expertise. Whether you require intricate designs or precise industrial components, we are committed to delivering excellence in every cut.

Reach out to us today to discuss your cutting needs and experience the difference with Accurate Cutting Services.

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.