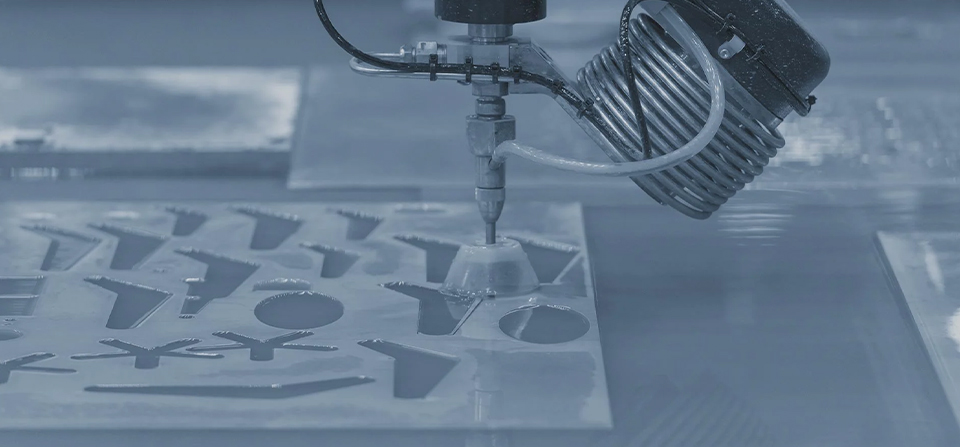

A Multi-Cutting Head Waterjet Cutting Machine is a highly advanced and Multifunctional industrial Equipment used in various industries for Systematic cutting of different materials. It utilizes high-pressure water mixed with an abrasive substance to cut through materials such as metal, stone, glass, ceramics, plastics, and composites. The key feature of this Multi Cutting Head Waterjet Cutting Machine is its ability to operate with multiple cutting heads, which allows for simultaneous cutting of several parts, significantly increasing productivity and reducing operational time.

The Waterjet Cutting Process is highly valued for its ability to produce clean and accurate cuts without generating heat-affected zones (HAZ), which can alter the material properties. This makes it ideal for materials that are sensitive to heat, such as certain metals, plastics, and thin sheets. The addition of multiple cutting heads allows for parallel processing, meaning that multiple pieces can be cut at the same time, increasing throughput and optimizing workflow in production environments.

Multi-cutting head systems are equipped with precise robotic arms or CNC-controlled systems that allow for accurate, repeatable cuts. The Diversity of this technology means it can be used for a wide range of applications, including prototyping, custom part manufacturing, and even intricate cutting patterns for design purposes.

Additionally, these Multi Cutting Head Waterjet Cutting Machines are environmentally friendly because they use water, a natural resource, for the cutting process. The abrasive material used in the water jet cutting process is often recyclable, minimizing waste.

A CNC Waterjet Cutting Machine is an Adaptable tool used in various manufacturing industries for cutting a wide range of materials. CNC stands for Computer Numerical Control, which means the machine is controlled by a computer program to carry out highly accurate cuts. The waterjet cutting process uses a high-pressure stream of water, sometimes mixed with abrasive materials like garnet, to slice through materials. This method is highly effective for cutting metals, ceramics, glass, plastics, stone, and composites.

One of the primary advantages of CNC waterjet cutting Machine is its ability to cut intricate shapes without generating heat. Unlike traditional cutting methods like laser or plasma cutting, waterjet cutting produces no heat-affected zones, reducing the risk of warping or changing the properties of the material being cut. This makes it especially useful for materials that are sensitive to temperature changes, such as metals that might distort or harden under high heat.

The CNC waterjet cutting Machine works by directing a stream of water through a small nozzle at extremely high pressures—often around 60,000 psi or higher. For harder materials, abrasive particles are added to the water to enhance cutting power. The computer-controlled system ensures precise movement of the nozzle, allowing for detailed, complex shapes and fine tolerances to be achieved.

An Abrasive Waterjet Cutting Machine is a specific type of waterjet cutting system that combines the high-pressure waterjet stream with abrasive materials to improve its cutting power. While a standard waterjet cutting machine uses only water to cut through materials, the abrasive waterjet includes finely ground abrasive particles, such as garnet, that are mixed with the water stream. This combination allows the machine to cut through harder and tougher materials that would otherwise be difficult to cut using pure water alone.

The Abrasive Waterjet Cutting Machine operates by directing a high-pressure stream of water through a small nozzle. At the same time, abrasive particles are introduced into the water stream through a mixing tube. The abrasive particles travel with the water, enhancing the cutting power of the jet. As the high-speed jet of water and abrasive material hits the surface of the workpiece, it erodes the material, effectively cutting it.

Abrasive waterjet cutting is ideal for a wide range of materials, particularly those that are hard or thick. This technology is especially useful in industries such as aerospace, automotive, construction, and manufacturing, where precision cutting of strong materials is essential.

A Gantry Type Waterjet Cutting Machine is a sophisticated cutting tool used in industries requiring high precision and the ability to cut through various materials. The primary feature of this machine is its gantry system, which acts as a bridge structure that supports the cutting head and ensures accurate movement in all three axes—X, Y, and Z.

The gantry in a waterjet cutting machine is essentially a framework that holds and moves the cutting head across the workpiece. The gantry is mounted on rails, allowing it to traverse along the X and Y axes, while the cutting head itself can also move vertically along the Z-axis for precise control over the cutting depth. This movement is all controlled by a computer numerical control (CNC) system, ensuring high levels of accuracy and repeatability in the cutting process.

The key benefit of a gantry type waterjet cutting machine lies in its ability to support heavy materials and larger workpieces. The structure is robust and provides stability, which is crucial for maintaining precision in cutting. This machine is especially effective when cutting large sheets of materials like metals, ceramics, glass, stone, and composites, making it ideal for industries such as aerospace, automotive, construction, and manufacturing.

The Gantry Type Waterjet Cutting Machine uses a high-pressure stream of water, sometimes mixed with abrasive particles, to cut through materials with exceptional accuracy. The gantry system allows the cutting head to follow intricate paths, delivering complex cuts and designs with minimal waste. Additionally, the gantry type machine’s flexibility enables it to perform tasks such as engraving, contour cutting, and creating custom shapes that are difficult to achieve with traditional cutting methods.

The gantry type waterjet cutting machine is known for its precision, reliability, and versatility, making it a preferred choice for applications requiring high-quality, intricate, and precise cuts on large workpieces.

A Standard Abrasive Waterjet Cutting Machine is a type of waterjet cutting system that uses a combination of high-pressure water and abrasive materials to cut through a wide range of materials. The "abrasive" component, typically garnet, is mixed with water to create a powerful cutting stream capable of slicing through hard and tough materials, such as metals, ceramics, stone, glass, and composites.

In this System, water is pressurized to extremely high levels—often up to 60,000 psi—and is then forced through a fine nozzle. The addition of abrasives to the waterjet stream significantly enhances its cutting ability, allowing it to cut through thicker or more difficult materials that a standard water-only jet cannot. The abrasive particles, carried along by the high-pressure water, erode the material's surface as the waterjet moves over it.

A key feature of a standard abrasive waterjet cutting machine is its CNC (Computer Numerical Control) system, which controls the movement of the cutting head along the X, Y, and Z axes with great precision. This allows for highly accurate cuts, intricate shapes, and fine tolerances, making it ideal for complex designs and detailed patterns.

This technology generates no heat during the cutting process. Unlike methods like laser or plasma cutting, the absence of heat means there is no risk of heat-affected zones (HAZ), which could distort or alter the material. This makes abrasive waterjet cutting ideal for materials that are sensitive to high temperatures or that need to retain their structural integrity.

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.