Apr 08, 2025 |

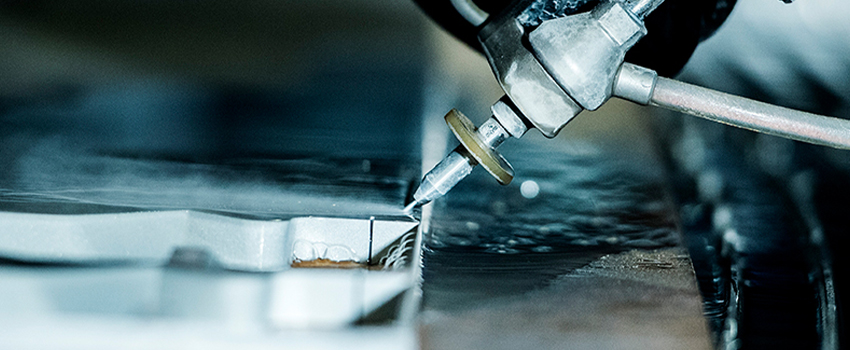

Waterjet Cutting Machine

Waterjet cutting is one of the most revolutionary technologies that has transformed the way materials are shaped. Whether you are working on a residential project, seeking unique designs for interior decorations, or need custom pieces for fabrication, waterjet cutting offers a range of benefits that make it one of the most reliable and accurate cutting solutions available.

This method allows for exceptional precision, intricate designs, and versatility with a wide range of materials. From metals and glass to stone, ceramics, and even plastics, waterjet cutting is the go-to solution for projects requiring accuracy and high-quality finishes. Let’s dive deeper into what waterjet cutting is, how it works, its importance in residential projects, its use in interior design and fabrication, and why you should choose us for your waterjet cutting needs.

Waterjet cutting is a modern manufacturing process that uses a high-pressure stream of water to cut through a variety of materials. Sometimes, an abrasive substance like garnet is mixed with the water to enhance the cutting power, especially when working with harder materials such as metal, stone, or glass. The precision and versatility of waterjet cutting make it a unique tool for industries ranging from aerospace to construction, and it is especially valuable for residential projects and custom designs.

Unlike traditional cutting methods that involve the application of heat (like lasers or plasma cutters), waterjet cutting doesn’t produce heat, which means that the material being cut does not get distorted or weakened. This is particularly important when working with heat-sensitive materials, such as certain metals, glass, and stone, where heat can affect the material's integrity and finish.

Waterjet cutting is capable of creating precise cuts with smooth edges, which is ideal for projects that require a clean, polished look. Whether you need straight cuts, intricate designs, or even complex three-dimensional shapes, Waterjet Systems allows you to execute these designs with unparalleled accuracy.

The process behind waterjet cutting is both fascinating and straightforward. At its core, it involves a highly pressurized stream of water being forced through a very fine nozzle. This water can be pressurized up to 60,000 psi (pounds per square inch) or more, which is many times the pressure of a typical household water supply. The pressurized water stream is directed precisely onto the material you wish to cut.

In cases where more cutting power is needed, an abrasive material such as garnet is mixed with the water to create an abrasive waterjet. This combination enhances the water’s ability to cut through tough materials, including metals and stone, making it highly effective for a wide variety of projects.

One of the significant advantages of Advanced Waterjet Technology is that the cutting process does not generate heat. This is a crucial factor when dealing with sensitive materials that could warp, melt, or lose structural integrity due to heat exposure. Additionally, waterjet cutting leaves smooth, clean edges that often require little to no post-processing, reducing the need for additional finishing steps.

Waterjet cutting also offers the ability to make very intricate cuts with high levels of detail, from sharp curves and angles to complex patterns. The precision of waterjet cutting allows it to create designs that would be difficult or impossible with other cutting methods.

When it comes to residential projects, homeowners often have specific, customized design requirements. Whether it’s for kitchen countertops, decorative wall features, flooring patterns, or any other home installations, precision and attention to detail are of the utmost importance. Waterjet Cutting Machine provides the flexibility to create these custom designs with impeccable accuracy, making it the ideal solution for a variety of residential applications.

For example, when designing a kitchen countertop, homeowners often seek unique, custom shapes, inlays, or edge details that reflect their personal taste. Waterjet cutting allows designers to execute intricate patterns in granite, marble, or quartz countertops with smooth edges and precise cuts. This level of detail is often challenging to achieve with traditional cutting methods, which can result in rough or uneven edges.

In addition to kitchen and bathroom applications, waterjet cutting is also widely used for custom tile work, staircases, and even custom furniture design. The ability to create smooth, clean edges is especially useful when working with delicate materials, such as glass or stone, which may crack or chip when subjected to traditional cutting processes.

By using waterjet cutting, homeowners can be confident that their designs will be executed with the highest level of quality and precision, giving their home a sophisticated and customized look.

Interior design is about more than just aesthetics; it’s about creating an environment that reflects the homeowner's personality and lifestyle. Waterjet cutting services play a crucial role in helping designers achieve these unique and personalized designs. Whether it’s a custom mosaic for a bathroom floor, a decorative panel for a living room wall, or a one-of-a-kind chandelier, Waterjet Cutter can transform your interior design dreams into reality.

One of the most significant benefits of waterjet cutting in interior design is the ability to work with a variety of materials, including glass, marble, stone, ceramics, and metals. Designers can use this technology to create intricate patterns, shapes, and even three-dimensional objects that fit seamlessly into the interior of a home or commercial space. From custom decorative panels to unique furniture elements, Water Jet Cutter offers endless possibilities.

Additionally, waterjet cutting’s ability to cut materials without generating heat makes it ideal for working with delicate materials like glass, where heat can cause warping or cracking. Whether it's glass flooring tiles, custom wall features, or delicate inlays, waterjet cutting ensures that the material maintains its original integrity and finish.

For interior designers & architects, waterjet cutting allows for creativity and customization without compromise. It offers the freedom to bring complex ideas to life with accuracy, making it easier to meet the specific needs of every design project.

In the fabrication industry, precision is key, and Waterjet Cutter Machine provides the accuracy required for fabricating custom parts and components. From structural elements to small, intricate components, waterjet cutting can produce parts with the exact specifications needed for a wide range of industries, including automotive, aerospace, construction, and more.

For example, when working on structural fabrication, waterjet cutting allows for precise cuts and detailed designs without causing any warping or distortion, which is especially important when working with metals. This is because the cutting process doesn’t generate heat, so there is no risk of altering the material's properties.

Moreover, Waterjet Cutting Machine can handle a wide variety of materials, including metals (stainless steel, aluminum, titanium), plastics, composites, and even stone. This versatility makes Waterjet Systems a highly sought-after solution for fabricators who need to work with different materials on a single project.

One of the key advantages of Waterjet Technology for fabrication is that it eliminates the need for additional finishing processes. The precision of the cuts means that parts can be produced with smooth, clean edges that require minimal or no further work. This leads to faster turnaround times and reduced labor costs, making waterjet cutting a highly efficient solution for fabrication projects.

At Accurate Cutting Service, we take pride in offering Top waterjet cutting solutions tailored to meet the unique needs of each client. Here are just a few reasons why you should choose us for your waterjet cutting projects:

We have completed numerous works for residential projects: Our extensive experience in the residential sector ensures that we can handle any custom cutting project with ease. Whether it’s a small kitchen remodel or a large-scale renovation, we deliver flawless results every time.

Knowledgeable team for residential works: Our skilled team is deeply familiar with the unique demands of residential projects. We take the time to understand your vision and work with you to bring it to life with precision and care.

We provide complex designs for interior design needs: No design is too complex for us. From elaborate floor patterns to detailed decorative elements, we specialize in creating intricate designs that meet the highest standards of quality.

Smart team for interior design needs: Our team is not only skilled but also highly creative, working closely with you to offer innovative solutions for your interior design projects. We ensure that each piece is customized to your specifications.

Experience in this field: With years of experience in the waterjet cutting industry, we bring expertise and a keen eye for detail to every project. You can trust us to handle your project with the utmost professionalism and skill.

Waterjet cutting is an incredibly versatile and efficient technology that offers unmatched precision, flexibility, and quality. Whether you're working on a residential project, looking for unique interior designs, or need custom fabrications, Waterjet Technology provides the perfect solution for all your cutting needs. With our experienced team and state-of-the-art equipment, we are ready to bring your ideas to life with the highest level of craftsmanship.

Choose Accurate Cutting Service for your waterjet cutting solutions, and let us help you create the perfect design that fits your vision.

Check out our other areas of expertise! In addition to waterjet cutting, we also offer CNC Laser Cutting, CNC Laser Welding, PVD Coating, Plasma Cutting, and Profile Cutting. We specialize in all types of mechanical works, ensuring precision and quality in every project. Let us handle your diverse cutting and fabrication needs!

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.