Mar 04, 2025 |

CNC Laser Cutting Services

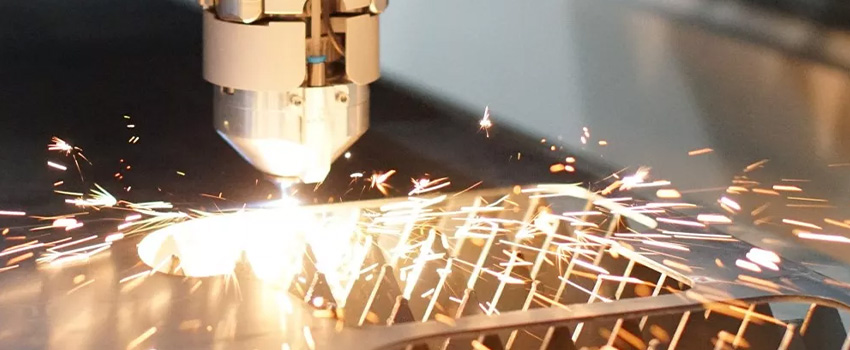

CNC Laser Cutting is a popular technology used in manufacturing to cut and engrave materials with high precision. It uses a focused laser beam controlled by a computer program to cut through materials with extreme accuracy. This method is often used in industries like automotive, aerospace, and signage due to its ability to produce detailed designs with minimal material waste.

CNC (Computer Numerical Control) laser cutting is a process that uses a laser to cut or engrave materials. The laser is a concentrated beam of light that can be directed very precisely by a computer-controlled system. This technology allows manufacturers to create parts with intricate designs and clean cuts. The CNC system uses programmed commands to control the movement of the laser cutter, making it highly accurate and capable of producing parts in complex shapes.

The CNC Laser Cutting Machine process is used on various materials such as metals, plastics, wood, and even glass. It is often chosen for its ability to make clean cuts without the need for physical contact with the material. CNC laser cutting is different from traditional cutting methods like saws or mechanical cutters because it uses a laser beam, which can focus on a tiny area, making it highly precise.

The CNC laser cutting process works by directing a high-powered laser beam onto a material, which is then melted, burned, or vaporized away to create a cut. Here's a simple breakdown of how it works:

Laser Generation: The laser cutter uses a high-powered laser source, typically a CO2 or fiber laser. This laser beam is created by exciting gas or solid-state lasers.

Focusing the Beam: The laser beam is directed through mirrors and lenses, which focus the beam onto the material’s surface. The focus point is very small, which increases the intensity of the laser and allows for precise cutting.

Cutting Process: The laser beam is aimed at the material, and as it interacts with the surface, it heats up and melts the material. In some cases, the material might even vaporize, depending on the type of material and laser power.

Assist Gas: In many laser cutting processes, an assist gas like oxygen or nitrogen is used. This gas helps to blow away the molten material, ensuring a clean cut and preventing any buildup on the material’s surface.

CNC Control: The entire process is controlled by a computer program. This program follows a design file, often created in CAD (Computer-Aided Design) software, to guide the laser along the correct path to make precise cuts.

The key advantage of CNC laser cutting is the ability to automate the process, which means it can produce parts with high consistency and low human intervention.

The CNC laser cutting process typically involves several key stages, which can be summarized as follows:

Design Stage: The first step is to create a design for the part to be cut. This is usually done using computer-aided design (CAD) software. The CAD file is then converted into a format that the CNC laser cutter can understand, often a G-code file.

Material Preparation: The material that will be cut is prepared. It might be in sheet form or large pieces depending on the project. The material is placed on the cutting bed, where it will be cut by the laser.

Laser Cutting: The CNC system activates the laser, and the laser beam follows the path defined in the design. The laser moves along the material, melting or vaporizing it, while an assist gas blows away the molten material to clear the cutting area.

Finishing: After the cutting process is complete, the parts are removed from the cutting bed. Sometimes, the edges may require additional finishing, such as sanding or cleaning, depending on the material and the quality of the cut.

Quality Control: The final stage is quality control, where the finished parts are inspected for accuracy, dimension, and quality. This ensures that the parts meet the required standards.

CNC laser cutting has a wide range of applications across various industries. Some common applications include:

Metal Cutting: In industries like automotive, aerospace, and construction, CNC laser cutting is used to cut metals with high precision. It’s often used for cutting sheet metal, steel, aluminum, and other metals used in manufacturing.

Signage and Advertising: Laser cutting is commonly used to create custom signs, logos, and displays. The ability to cut intricate shapes and detailed designs makes it ideal for producing eye-catching and professional signs.

Electronics: In the electronics industry, CNC laser cutting is used to create components like circuit boards, enclosures, and housings. The precision of laser cutting ensures that even small and delicate parts can be made accurately.

Aerospace: CNC Laser Cutting Machine is crucial in the aerospace industry for producing lightweight and complex parts. CNC laser cutting allows manufacturers to create parts that meet strict tolerances and quality standards.

Woodworking and Furniture: CNC laser cutting is also used in woodworking for cutting intricate patterns and designs into wood, creating decorative pieces or even custom furniture parts.

Textile and Leather: CNC laser cutters are used to cut fabrics and leather for applications such as fashion, upholstery, and accessories. Laser cutting allows for very detailed and accurate cuts, which is especially useful for creating custom designs.

CNC laser cutting offers several advantages over traditional cutting methods. Some of the main benefits include:

Precision: CNC laser cutting is extremely precise, with the ability to cut intricate and complex designs that would be difficult or impossible to achieve with other methods.

Speed: Laser cutting is faster than many traditional methods. The CNC system can quickly move the laser along the material, speeding up the production process.

Minimal Material Waste: Laser cutting is highly efficient, making it ideal for projects that require minimal material waste. The narrow laser beam means that less material is removed during the cutting process.

No Tool Wear: Since the laser doesn’t physically touch the material, there’s no tool wear. This means that there’s no need for frequent tool replacement, which can be costly and time-consuming in traditional cutting methods.

Versatility: CNC laser cutting can be used on a wide range of materials, including metals, plastics, wood, and glass. This makes it a versatile option for many industries.

Automation: The CNC system allows for automation of the cutting process, reducing human intervention and improving consistency and repeatability.

Clean Cuts: The laser produces clean, smooth edges without the need for additional finishing. This is particularly important in industries where high-quality parts are required.

CNC Laser Cutting Machine is known for its exceptional accuracy and precision. The accuracy of the cut is influenced by several factors, including the type of laser, the material being cut, and the thickness of the material. Generally, CNC laser cutting can achieve tolerances of around ±0.1 mm or better, depending on the machine and settings.

The laser beam is focused on a small point, allowing for very fine cuts. Additionally, the CNC system ensures that the laser follows the programmed path exactly, which contributes to the high precision of the process.

In terms of repeatability, CNC laser cutting is highly reliable. The computer control system ensures that each part is made exactly the same, making it ideal for large-scale production where consistency is important.

The cost of CNC laser cutting depends on several factors, including the material, thickness, complexity of the design, and the quantity of parts required. Generally, CNC laser cutting can be more expensive than traditional cutting methods due to the initial investment in equipment and the expertise needed to operate the machine.

However, because CNC Laser Cutting Machine is precise and minimizes material waste, it can be more cost-effective in the long run for complex or large-scale production runs. Other factors that can affect cost include:

Material Type: Some materials, like metals, are more expensive to cut compared to plastics or wood. The cost of materials also affects the overall price.

Cutting Time: More intricate designs or thicker materials may take longer to cut, which can increase the overall cost.

Batch Size: Larger quantities may reduce the cost per unit, making it more affordable for mass production.

For a more accurate quote, it’s best to consult with a CNC laser cutting service provider, as they can give you a detailed estimate based on your specific project needs.

CNC laser cutting machines are versatile and can cut a wide variety of materials. Some common materials that can be cut using CNC laser cutting include:

Metals: Steel, stainless steel, aluminum, brass, and copper are commonly cut using CNC laser machines. The laser’s ability to focus on a small area allows for precise cuts in these often tough and thick materials.

Plastics: Acrylic, PVC, polycarbonate, and other plastics can be easily cut with a laser. Laser cutting plastic is popular in industries like signage and custom product manufacturing.

Wood: CNC laser cutting is widely used in woodworking to create intricate designs and patterns. Wood can be cut, engraved, and etched with high precision.

Leather: Leather is another material that can be cut with CNC laser machines, which is useful for industries like fashion, accessories, and upholstery.

Textiles: Fabrics such as cotton, polyester, and nylon can also be cut using a CNC laser cutter. The laser cuts cleanly without fraying edges, which is ideal for fashion design and textile manufacturing.

Glass: Some CNC Laser Cutting Machine can even cut glass, although this is a more specialized application.

Overall, CNC laser cutting is a versatile process that can be used on a wide range of materials, making it ideal for many different industries and applications.

CNC laser cutting is a powerful and precise method of cutting materials, offering advantages like speed, accuracy, and versatility. By using computer control to direct a high-powered laser, this technology is used in a wide range of industries to produce high-quality parts with minimal waste. Whether cutting metals for automotive parts, creating signage, or designing intricate patterns in wood, CNC laser cutting is an essential tool in modern manufacturing. Its ability to work with various materials and produce detailed designs makes it an invaluable technology for many industries.

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.