Jan 14, 2025 |

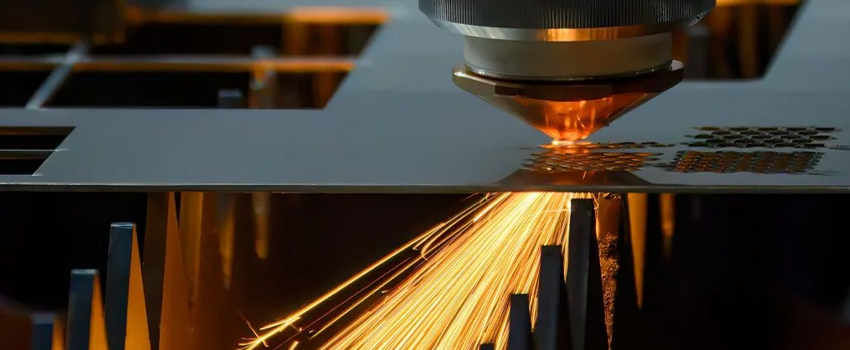

CNC Laser Cutting

CNC Laser Cutting is a precision manufacturing process that uses a high-powered laser beam controlled by a computer to cut, engrave, or etch various materials. This technology ensures intricate and accurate cuts, making it ideal for industries such as automotive, aerospace, medical devices, electronics, and more. CNC Laser Cutting Machine offers several advantages, including high precision, minimal material waste, fast production speeds, and the ability to work with a variety of materials like metals, plastics, and wood. It eliminates the need for physical tools, resulting in reduced maintenance and tool wear. Whether you need complex patterns or simple shapes, CNC laser cutting provides clean, smooth edges with minimal post-processing required. Our CNC Laser Cutting Services combine advanced technology, skilled technicians, and custom solutions to meet your specific needs, ensuring quality, efficiency, and cost-effectiveness for every project.

CNC Laser Cutting is a manufacturing process that uses a high-powered laser beam to cut, engrave, or etch materials. The term "CNC" refers to "Computer Numerical Control," which means the laser cutting machine is controlled by a computer program that directs the laser beam's movements with high precision. This allows for complex and highly accurate cuts on various materials, including metals, plastics, wood, and more.

Laser cutting is a versatile and highly efficient process. It utilizes a laser beam to melt, burn, or vaporize the material, creating precise cuts or engravings. The laser itself is focused into a fine beam that is directed onto the material's surface using mirrors and lenses. CNC technology ensures that this beam follows the exact pattern programmed into the system, achieving precision and repeatability.

Laser Source: The component that generates the laser beam.

CNC Controller: The computer that controls the movement of the laser and other machine components.

Material: The workpiece being cut or etched.

The CNC laser cutting process can handle materials of various thicknesses and densities, making it highly adaptable for different applications.

CNC laser cutting has a wide range of applications across a range of industries. Its precision, flexibility, and efficiency make it suitable for many different sectors. Some of the primary industries that utilize CNC laser cutting services include:

The automotive industry relies heavily on CNC Laser Cutting Machine to produce parts such as body panels, brackets, and structural components. The precision of laser cutting ensures that parts are manufactured to exact specifications, which is critical for assembly line and vehicle safety. Laser cutting is also used to create intricate designs in automotive bodywork and interior features.

In aerospace manufacturing, precision is paramount. CNC laser cutting is used to create lightweight, complex components used in aircraft and spacecraft. Materials used in aerospace applications, such as high-strength alloys and composites, benefit from laser cutting's ability to cut with minimal distortion, ensuring that parts meet tight tolerance standards.

The medical device industry requires highly precise components to meet regulatory standards and functional requirements. CNC laser cutting machines allow for the production of delicate components such as surgical instruments, implants, and diagnostic devices with a high level of accuracy. In addition, the clean cuts of the process reduce the need for post-processing, which is crucial for meeting strict hygiene standards.

The electronics industry uses CNC laser cutting to produce parts such as circuit boards, housings, connectors, and enclosures. Laser cutting enables the production of complex patterns and micro-cuts required for modern electronics, where even the smallest imperfections can cause malfunctions.

Architectural designs often involve detailed patterns, engravings, and intricate shapes. CNC laser cutting is used in the production of decorative features, custom metalwork, and structural components. From cutting metal cladding to creating unique artistic designs for interiors, laser cutting plays a key role in architecture and construction.

CNC Laser Cutting is widely used in the signage industry, especially for creating custom designs for business signs, logos, and other marketing materials. The precision of the laser ensures that even the most detailed designs can be cut into materials such as acrylic, metal, and wood.

The furniture industry also benefits from CNC laser cutting, especially for creating intricate designs and patterns in wood and metal furniture. Laser cutting allows for the precision cutting of intricate shapes, which is essential for modern, high-end furniture designs.

CNC laser cutting is gaining popularity in the fashion industry for creating delicate and intricate patterns in fabrics and leather. From custom textile designs to intricate leather cutouts, CNC laser cutting is transforming fashion production with its ability to create clean and intricate patterns.

The CNC laser cutting process is a highly automated and efficient method for creating precise cuts. Here's a step-by-step breakdown of how the process works:

The process starts with designing the pattern or cutting path. This is done using CAD (Computer-Aided Design) software, which allows engineers and designers to create detailed designs of the object to be cut. The design is then converted into a machine-readable format, typically a DXF or SVG file, which is uploaded into the CNC system.

Next, the material to be cut is placed on the laser cutting bed. The material is held in place by clamps or magnets to prevent movement during the cutting process. Depending on the material type, it may be preheated or treated to ensure optimal cutting results.

Before starting the cutting process, the CNC operator sets the necessary parameters, such as the laser power, cutting speed, and the gas to be used (commonly oxygen, nitrogen, or compressed air). These parameters are adjusted depending on the thickness, material, and desired quality of the cut.

The laser cutting machine begins the cutting process. The CNC system directs the laser beam along the designated cutting path with high precision. The laser melts, burns, or vaporizes the material, leaving behind a clean cut. The cutting process is controlled in real time, ensuring that the laser maintains the exact path specified in the design.

Once the cutting is complete, the material may undergo a secondary process such as cleaning, polishing, or etching, depending on the requirements of the project. However, in many cases, the CNC laser cutting process leaves edges that are so clean that minimal post-processing is necessary.

CNC laser cutting offers several advantages over traditional cutting methods. Here are some of the key benefits:

One of the biggest advantages of CNC Laser Cutting Service is its incredible precision. Laser cutting systems can cut parts with tolerances as tight as ±0.01mm. This level of accuracy is impossible to achieve with traditional cutting methods, making CNC laser cutting ideal for industries that require highly detailed work.

Because laser cutting uses a narrow beam and can cut with extreme precision, it minimizes material waste. The cutting process generates minimal heat, which reduces the risk of material distortion. Additionally, intricate designs that maximize the use of material can be easily executed, resulting in lower costs and less waste.

CNC laser cutting is a fast process. Once the machine is programmed, it can cut large quantities of identical parts with little to no human intervention. The cutting speed, combined with the automation provided by CNC, allows for mass production without compromising on quality.

CNC Laser Cutting can be used to cut a wide variety of materials, including metals, plastics, wood, and glass. This versatility makes it suitable for diverse applications across many different industries. Additionally, laser cutting can perform other functions like engraving, marking, and perforating.

The laser cutting process is cleaner than many traditional methods. The laser beam generates little heat, reducing the likelihood of harmful fumes, sparks, and the need for extensive cleanup. It also has a minimal impact on the surrounding environment, making it a safer choice for both operators and the workplace.

Unlike traditional cutting methods, where tools wear down over time and require replacement, CNC laser cutting doesn’t involve any physical contact between the laser and the material. This eliminates the need for frequent tool changes and results in fewer maintenance issues.

When it comes to CNC laser cutting services, our company stands out as a leader in the field. Here are a few reasons why choosing us is the best decision for your cutting needs:

We utilize state-of-the-art CNC Laser Cutting Machine that offer the highest precision and quality. Our technology is always updated to stay ahead of industry standards, ensuring that we provide the best possible service to our clients.

Our team of engineers and technicians are highly trained and experienced in CNC laser cutting. They understand the intricacies of different materials and can adjust the cutting parameters to ensure that every project is completed to perfection.

We pride ourselves on offering fast and reliable service. With our efficient CNC Laser Cutting machines, we can handle both small-scale and large-scale production runs, ensuring quick turnarounds without sacrificing quality.

We understand that each project is unique. Our team works closely with clients to offer tailored solutions that meet specific requirements. Whether you need custom designs, specialized materials, or unique cuts, we can help bring your vision to life.

We offer high-quality CNC laser cutting services at competitive prices. We strive to provide our clients with cost-effective solutions without compromising on quality, making us an excellent choice for businesses of all sizes.

Our customer support team is always available to answer questions, provide guidance, and assist with any issues that may arise. We prioritize customer satisfaction and work hard to ensure a smooth and seamless experience for every client.

Ready to get started with CNC laser cutting services? Our team is here to help. Whether you have a question or are ready to discuss your next project, we encourage you to reach out to us today.

Phone: +91 9979228016

Email: acs.cutting@gmail.com

Website: https://www.acscutting.com/

Let us assist you in bringing your ideas to life with precision and efficiency through our expert CNC laser cutting services. Contact us now to get a quote or discuss your specific requirements!

Accurate Cutting Services is one of the most reputable names in CNC Laser Cutting & Other Cutting Services. Our expert team works with utmost professionalism, and we have successfully completed numerous projects across India and in several other countries such as Kenya, Nigeria, Nairobi, and many more.

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.