Jan 28, 2025 |

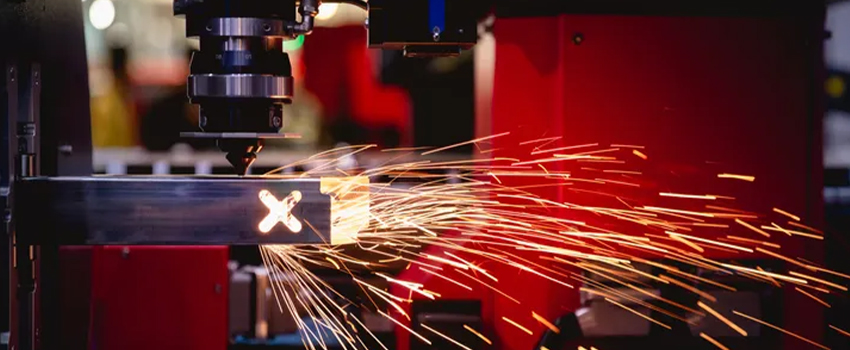

CNC Laser Cutting Services

CNC Laser Cutting Machine offer significant advantages over traditional cutting methods, particularly in metal cutting. One of the primary benefits is the reduced power consumption; CNC Laser Cutting typically operate at about 10 kW, much lower than the 50 kW power required by conventional cutting processes. This not only makes them more energy-efficient but also faster in terms of cutting speed. The laser's focused narrow beam moves precisely along the lines programmed into the CNC system, much like a pencil drawing on paper, allowing for intricate and highly accurate cuts.

Moreover, CNC Laser Cutting is versatile and capable of cutting a wide range of materials, including metals, plastics, wood, and more. They also offer the ability to control the beam intensity, length, and heat output, further enhancing precision. The non-contact nature of laser cutting reduces the risk of damaging surrounding areas, and it minimizes the need for post-cutting processing since the cuts are smooth and precise.

Maintenance costs are lower compared to conventional cutting methods as laser cutters have fewer moving parts and inexpensive components. Additionally, CNC Laser Cutting Machine allow for quick setup changes, increasing operational efficiency. Overall, CNC laser cutting provides a highly efficient, cost-effective, and precise solution for metal cutting.

CNC laser cutting differs from traditional cutting methods in several key ways, offering distinct advantages in precision, efficiency, and versatility. Here are some of the main differences:

Offers extremely precise cuts due to the narrow, focused laser beam. The accuracy is generally within a few microns, allowing for intricate designs and fine detailing.

Methods like saw cutting, plasma cutting, and water jet cutting can be less precise, especially when dealing with complex shapes. They may require additional finishing work to achieve a similar level of accuracy.

CNC Laser Cutting Machine is typically faster, especially for thin materials. The high speed is due to the laser's ability to cut continuously without mechanical movement involved in the cutting process.

Methods like saw cutting or water jet cutting can be slower as they involve physical contact with the material, which can create friction and slow down the process.

Capable of cutting a wide variety of materials, including metals, plastics, wood, and ceramics, with excellent precision.

May be more limited in terms of material compatibility. For instance, saw cutting is typically restricted to wood and certain metals, while plasma cutting is most effective on thicker metals.

Generally consumes less power, often operating at around 10 kW compared to other cutting methods.

Methods like plasma cutting and water jet cutting tend to consume much more energy, often requiring upwards of 50 kW.

Since it’s a non-contact process, there is less wear and tear on the equipment, and the material is not subjected to physical forces that could cause distortion.

Most traditional methods, such as saw cutting, involve direct contact with the material, which can result in burrs, heat-affected zones, or distortion of the material.

Requires lower maintenance since it has fewer moving parts and typically needs less frequent servicing.

Mechanical wear and tear on tools (e.g., saw blades, punches) often leads to higher maintenance costs and more frequent tool replacements.

Produces smooth, clean cuts with minimal heat-affected zones, often reducing the need for post-processing.

Methods like mechanical cutting may leave rough edges, requiring additional finishing steps such as sanding or grinding.

CNC Laser Cutting Machine is the most required tool across multiple industries due to its precision, speed, and versatility. In the manufacturing sector, it enables the creation of complex parts with high accuracy, improving the production of machinery, automotive components, and aerospace components. The electronics industry benefits from laser cutting’s ability to create fine, detailed circuits and micro-components, ensuring high-quality products. In metalworking, it provides clean and efficient cuts on various metals, from stainless steel to aluminum, used in construction, automotive, and heavy equipment.

In architecture and construction, laser cutting is used to create intricate designs in metal, glass, and wood, offering both functional and aesthetic value. The textile industry uses laser cutters to precisely cut fabric for garments and industrial applications. Furthermore, laser cutting’s non-contact nature reduces wear on tools and minimizes material wastage, making it both cost-effective and environmentally friendly. Its versatility and ability to adapt to different materials make it indispensable across industries.

At Accurate Cutting Service, we pride ourselves on being leaders in the CNC laser cutting industry, offering unmatched precision, efficiency, and quality. Here’s why we are the best choice for your CNC laser cutting needs:

Our state-of-the-art CNC laser cutting machine is designed to deliver intricate and highly accurate cuts, ensuring your project meets the highest standards. With micron-level precision, we handle everything from simple cuts to complex, detailed designs.

We can cut a wide range of materials, including metals, plastics, wood, and more. Whether it's stainless steel, aluminum, acrylic, or composite materials, our machines are capable of providing superior results across various industries.

With advanced technology and expert operators, we deliver quick turnaround times without compromising on quality. Our cutting-edge machines reduce material waste and improve overall efficiency, saving you both time and money.

Our CNC laser cutting is not only precise but also cost-efficient. We offer competitive pricing without sacrificing quality, making our services the most cost-effective solution for both small and large-scale projects.

With years of industry experience, our skilled team ensures that every job is completed to perfection. We work closely with our clients to understand their unique needs and provide customized solutions.

We are committed to delivering outstanding customer service and support throughout the entire process. From initial consultation to final product delivery, we ensure timely communication and satisfaction every step of the way.

At Accurate Cutting Service, we are dedicated to providing high-quality CNC laser cutting services tailored to your unique needs. Whether you’re looking for precision cuts on metal, plastics, wood, or other materials, our advanced technology and expert team are here to help. We offer fast, reliable, and cost-effective solutions for projects of all sizes.

Get in Touch: If you have any questions or would like to request a quote, please don’t hesitate to reach out. Our team is ready to assist you with all your CNC laser cutting needs.

Phone: +91 9979228016

Email: acs.cutting@gmail.com

Address: 336/9, GIDC Industrial Estate Makarpura, Vadodara, Gujarat, India-390 010

You can also fill out our online contact form, and one of our specialists will get back to you promptly. We’ll work closely with you to understand your project requirements and ensure you receive the best service possible.

Contact us today and let us help you bring your ideas to life with our cutting-edge CNC laser cutting technology!

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.