Fab 25, 2025 |

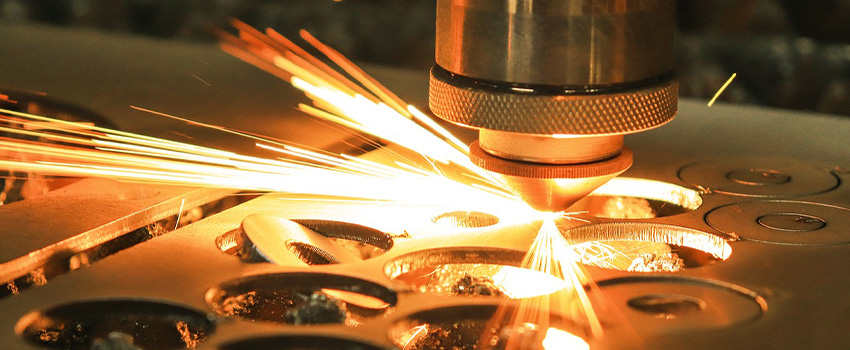

CNC Laser Cutting Services

Welcome to Accurate Cutting Services! We specialize in providing superior quality Cutting Service with High Tech CNC Laser Cutting Machine for a wide range of industries. With advanced technology and a team of skilled professionals, we deliver precise, efficient, and cost-effective cutting solutions customised to meet your specific needs. Whether you require custom designs, prototyping, or large-scale production runs, our laser cutting services are designed to offer the best possible results.

CNC Laser Cutting is a precision process that uses a laser beam controlled by a Computer Numerical Control (CNC) system to cut, engrave, or etch materials with high accuracy. This advanced technology harnesses a focused laser beam to melt, burn, or vaporize materials, allowing for intricate cuts and complex designs with minimal waste. CNC laser cutting can be used with a wide variety of materials, including metals, plastics, wood, acrylic, and even textiles.

The CNC system ensures that each cut is precise and follows the digital design specifications. By converting designs from CAD (Computer-Aided Design) files into machine movements, CNC laser cutting can produce highly detailed and repeatable cuts quickly. This makes it perfect for industries that require precision, such as automotive, aerospace, electronics, and manufacturing.

With CNC laser cutting, it’s not just about cutting materials—it’s about achieving the highest quality with minimal effort and at a faster pace. The technology is highly versatile and can handle both small and large production runs, making it an essential tool for modern manufacturing processes.

CNC laser cutting works by directing a focused laser beam onto the material to be cut. Here’s a simple breakdown of the process:

Design Creation: It starts with creating a digital design using CAD (Computer-Aided Design) software. This design contains all the dimensions and details needed for the cutting process.

Machine Setup: The digital design is converted into a set of instructions (known as G-code) that tells the CNC machine exactly how to move the laser. These instructions control the laser's power, speed, and focus to ensure accurate cutting.

Material Placement: The material to be cut is placed on the CNC laser cutting machine’s work surface. The machine is equipped with sensors and positioning systems to ensure that the material is properly aligned.

Laser Cutting: The laser beam, controlled by the CNC system, is directed at the material. The intense heat from the laser melts, burns, or vaporizes the material, creating a precise cut along the predefined path. The CNC system monitors the process, ensuring that each cut meets the specifications of the digital design.

Completion and Inspection: Once the cutting process is completed, the finished parts are inspected to ensure they meet quality standards. Because the process is highly accurate, the parts usually require little to no additional finishing.

CNC Laser Cutting Machine offers numerous benefits, making it a preferred choice for industries that require precision, efficiency, and versatility. Below are some key advantages of using CNC laser cutting for your projects:

CNC laser cutting delivers exceptional accuracy, achieving intricate and detailed cuts with fine tolerances. The laser follows the exact design specifications, ensuring that every part is consistent, even in complex shapes.

Laser cutting is faster than many traditional cutting methods. The high-speed nature of the process helps minimize production time, making it ideal for both small and large projects. Quick turnaround times mean you can get your parts faster and reduce downtime.

Because the laser beam creates a narrow cut, there is less material waste compared to traditional cutting methods. This reduces production costs, especially when working with expensive materials. Efficient material nesting further minimizes waste.

CNC laser cutting can be used to cut a wide variety of materials, including metals (steel, aluminum), plastics, wood, acrylics, rubber, and more. It’s a highly adaptable process that suits many industries, from automotive to signage.

Laser cutting allows for the creation of complex, intricate designs that are difficult or impossible to achieve with traditional methods. It’s ideal for custom projects, intricate patterns, and small or delicate cuts.

Unlike mechanical cutting methods, the laser beam doesn’t wear out, which means there is no tool wear. This results in consistent quality over long production runs with minimal maintenance and no need to replace cutting tools.

Laser cuts are clean and precise, often eliminating the need for additional finishing processes such as sanding, deburring, or polishing. This can save time and reduce labor costs.

CNC laser cutting is highly automated, which means the same cut can be repeated with precision, even for large batches. Once set up, the machine can continuously produce identical parts without manual intervention, improving consistency and efficiency.

Since CNC laser cutting is controlled digitally, making design modifications is quick and easy. You can easily adjust designs or switch between different designs without significant downtime or tool changes.

CNC laser cutting is not just limited to simple shapes it can handle both 2D and 3D applications with remarkable accuracy.

2D CNC laser cutting is ideal for creating flat, intricate shapes and detailed designs from sheet materials such as metal, acrylic, and wood. Some common applications include:

Signage and Branding: Laser cutting can produce highly detailed logos, letters, and signs for businesses and events.

Industrial Components and Panels: Laser cutting is used for creating precise components used in machinery, automotive parts, and electronics.

Architectural Designs: Laser cutting is commonly used for creating architectural features like windows, panels, and decorative elements.

Custom Decorative Elements: From artwork to personalized gifts, laser cutting can create unique designs in a variety of materials.

For more complex projects, 3D CNC laser cutting allows the creation of parts with intricate contours, curved surfaces, and three-dimensional shapes. This process is particularly beneficial in industries where precision and flexibility are crucial, such as:

Aerospace and Automotive Industries: 3D laser cutting is used to create custom parts, prototypes, and components with complex shapes.

Prototypes for Product Development: When developing new products, 3D laser cutting can quickly and precisely create prototypes for testing and design validation.

Sculptures and Models: Artists and designers use 3D laser cutting to create sculptures, models, and architectural models.

Complex Industrial Components: For components that require precision and the ability to handle multiple angles and curves, 3D laser cutting provides unmatched design freedom.

CNC laser cutting has revolutionized the manufacturing industry, providing unmatched precision, speed, and versatility. Whether for small projects, large-scale production, or complex 3D designs, CNC laser cutting remains one of the most advanced and efficient cutting technologies available today.

At Accurate Cutting Services, we are committed to providing high-quality CNC laser cutting services that meet the diverse needs of various industries. With our state-of-the-art equipment, skilled team, and dedication to excellence, we can help bring your design ideas to life with precision and efficiency.

We offer cutting services with a CNC laser cutting machine across various industries and have extensive experience delivering exceptional results. Whether you’re based in Vadodara, Gujarat, or anywhere across India, we are here to provide the highest-quality laser cutting services for your needs.

Contact us today to learn more about how our CNC laser cutting services can benefit your business!

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.