Mar 11, 2025 |

CNC Laser Cutting Services

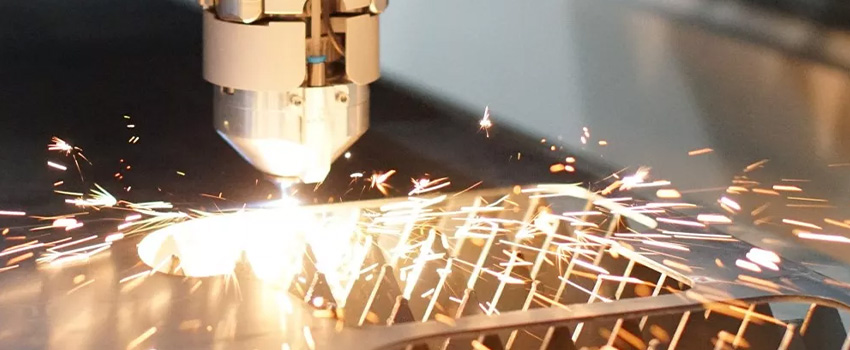

CNC Laser Cutting, also known as Engraving, is a state-of-the-art technology used for precision cutting, engraving, and marking on various materials, including metals, plastics, and wood. At Accurate Cutting Service, we specialize in providing cutting-edge solutions for both industrial and commercial projects. With our advanced CNC Laser Cutting Machine, we deliver exceptional accuracy and high-quality results, making it easier for clients to achieve their desired designs.

By using the latest technology, we ensure clean cuts, minimal waste, and faster turnaround times, making our CNC Laser Cutting service an ideal choice for businesses looking for precision and reliability. Whether it’s for manufacturing parts or intricate engravings, Accurate Cutting Service offers customized solutions that meet the highest industry standards. Our expertise and commitment to quality make us a trusted partner for your laser cutting needs.

A CNC Laser Cutting Machine is an advanced technology used for cutting and engraving a wide variety of materials with high precision. CNC stands for Computer Numerical Control, which means the machine is controlled by a computer program that directs the cutting process. Laser cutting uses a high-powered laser beam to melt, burn, or vaporize material along a precise path. This process results in clean, accurate cuts with minimal material waste.

CNC Laser Cutting machines are widely used in industries such as manufacturing, automotive, aerospace, and electronics, as well as in commercial applications. The primary advantage of using laser cutting over traditional methods is its ability to cut through materials with extreme precision, often down to a fraction of a millimeter. It can work with a range of materials including metals, plastics, wood, and composites.

The machine operates by focusing the laser beam onto the material's surface, where it melts the material to create a cut. In addition to cutting, these machines can also be used for engraving, marking, and etching. CNC Laser Cutting provides high-speed production, reduced costs, and the ability to create complex designs that would be difficult or impossible to achieve with other methods. Its versatility and accuracy make it a valuable tool in modern manufacturing.

The process of CNC Laser Cutting works by using a high-powered laser beam controlled by a computer to precisely cut through materials. Here’s how the cutting process works step by step:

Design Creation: The first step is to create a digital design of the part or shape that needs to be cut. This design is usually made in a Computer-Aided Design (CAD) software, which outlines the exact dimensions and shape of the material.

Programming: The CAD design is converted into a code that the CNC machine can understand. This code is known as G-code, which specifies the movements and actions the laser cutting machine will take during the cutting process.

Material Setup: The material to be cut, whether it’s metal, wood, plastic, or another type, is securely placed on the machine bed. Depending on the material, the machine settings (such as laser power, cutting speed, and focal length) are adjusted accordingly.

Laser Beam Activation: Once the machine is set up, the laser beam is activated. The laser is directed through mirrors and lenses to focus on the material's surface. The intense heat of the laser melts, burns, or vaporizes the material along the cutting path.

Cutting Process: The CNC system guides the laser along the design path, cutting through the material. The machine can operate continuously, producing highly precise cuts without human intervention.

Finishing: After the cut is complete, the material is removed, and any excess debris or material left behind is cleaned up. In some cases, additional processes like engraving or marking can be done after the initial cut.

CNC Laser Cutting is highly regarded for engraving due to several key advantages that make it the best choice for precision and quality. Here's why:

High Precision: CNC Laser Cutting Machine can engrave with extreme accuracy, down to fractions of a millimeter. This precision ensures that intricate designs, fine details, and complex patterns are replicated with high fidelity, which is especially important for engraving work.

Versatility with Materials: CNC laser engraving can be performed on a wide variety of materials, including metals, wood, plastics, ceramics, glass, and even stone. This versatility makes it an excellent choice for a wide range of engraving projects, whether it's for personalizing products, creating detailed artwork, or marking industrial parts.

Clean, Smooth Finish: Laser engraving results in clean, smooth surfaces with minimal post-processing required. The laser beam doesn't physically contact the material, which prevents any distortion, wear, or rough edges that could occur with traditional engraving methods.

No Contact or Tool Wear: Unlike mechanical engraving methods that require tools to physically touch the material, laser engraving is a non-contact process. This reduces the risk of tool wear and eliminates the need for constant tool replacements, saving time and cost in the long run.

High Speed and Efficiency: Laser engraving is faster than many traditional methods. With CNC laser cutting, the engraving process is automated, meaning it can run continuously and achieve consistent results with minimal downtime.

Customization and Intricacy: CNC laser cutting allows for highly customizable designs and the ability to engrave fine, intricate patterns that would be difficult or impossible to achieve with manual engraving methods. This is particularly valuable for personalized items, logos, or detailed artwork.

Minimal Material Waste: The laser’s precision ensures that only the required material is removed, leading to minimal waste. This is both cost-effective and environmentally friendly.

CNC laser cutting machines have become an integral part of manufacturing industries due to their numerous benefits. Their precision, efficiency, and versatility make them a preferred choice for a wide range of applications. Here are some key reasons why CNC laser cutting machines are essential in manufacturing:

CNC laser cutting machines provide unmatched accuracy, allowing manufacturers to achieve tight tolerances and intricate designs. The high precision ensures that parts fit together perfectly, which is critical in industries like aerospace, automotive, and electronics.

Laser cutting is a fast process, reducing production times significantly. It allows manufacturers to produce large quantities of parts quickly while maintaining high-quality standards. The automation of CNC machines further enhances efficiency, enabling continuous, high-speed production.

CNC laser cutting machines can cut through a wide range of materials, including metals, plastics, wood, and composites. This versatility makes them suitable for various manufacturing sectors, from creating complex metal components to delicate plastic parts.

The precision of CNC laser cutting results in minimal material wastage. The laser cuts with extreme accuracy, meaning that only the required material is removed, reducing overall production costs and making it an environmentally friendly choice.

Since the laser is a non-contact process, there is no physical wear on tools. This eliminates the need for constant tool replacement and maintenance, lowering operating costs and increasing the longevity of the machinery.

CNC Laser Cutting allows manufacturers to create highly complex and intricate shapes that would be difficult, if not impossible, to achieve with traditional cutting methods. This is particularly beneficial for industries that require custom or detailed designs, such as the automotive and aerospace sectors.

Laser cutting results in clean, smooth cuts, often eliminating the need for additional finishing or post-processing steps like deburring or polishing. This saves time and resources in the manufacturing process.

CNC Laser Cutting Machine can repeat the same cut with consistent quality across multiple parts. This is vital for mass production runs, where uniformity is essential.

The CNC laser cutting process is automated, reducing the need for manual intervention. This reduces labor costs and the likelihood of human error, resulting in more reliable and cost-effective production.

In commercial and architectural applications, the need for precision is paramount. CNC laser cutting machines provide unparalleled accuracy, enabling intricate patterns, fine details, and complex designs to be cut with high precision. This level of accuracy is essential for creating architectural facades, custom signage, decorative elements, and other architectural features that require tight tolerances.

CNC laser cutting allows for a high degree of customization, which is essential for both commercial and architectural projects. Whether it’s a unique architectural feature, personalized signage, or decorative panels, the ability to work with detailed, custom designs is a significant benefit. Laser cutting also enables the use of various materials such as metal, acrylic, wood, and even glass, providing more options for creative expression.

Architectural and commercial projects often require complex shapes and geometries that would be challenging to achieve with traditional cutting methods. CNC laser cutting machines can easily handle intricate patterns, curves, and angular cuts that add aesthetic value to the design while maintaining structural integrity. This is particularly useful for decorative elements like perforated metal screens, lattice work, and intricate facades.

In commercial and architectural design, speed is critical to meet deadlines and client expectations. CNC laser cutting offers fast prototyping, allowing architects and designers to quickly create mock-ups or prototypes to test their ideas before committing to full-scale production. This quick turnaround ensures that changes can be made efficiently, saving both time and money during the design phase.

Laser cutting is known for its minimal material waste due to the high precision of the cut. In both commercial and architectural applications, this reduces material costs, making it a cost-effective option for large-scale projects. Additionally, the minimal heat-affected zone ensures that the material is not distorted, maintaining the integrity of the design.

Laser cutting results in clean, smooth edges that often require little to no additional finishing or post-processing. This is especially important in commercial signage or architectural elements that need to have a polished, professional appearance. The precise cuts made by a laser cutting machine ensure that no further refinishing is required, which saves both time and effort.

In architectural applications, materials like metal are often used for both structural and decorative purposes. CNC Laser Cutting ensures that the parts created are strong, durable, and can withstand the elements over time. For commercial projects, durable signage and functional elements are critical for longevity, and laser cutting ensures they stand the test of time without degradation in quality.

Laser cutting enables architects to explore innovative, modern design concepts that incorporate intricate patterns, perforations, and layers, contributing to visually striking structures and facades. From the facade of a commercial building to artistic installations in public spaces, laser-cut elements can transform the aesthetic appeal of a project, giving it a contemporary, cutting-edge look.

The automation of CNC laser cutting machines reduces the need for manual labor, resulting in lower labor costs for both commercial and architectural projects. The machines can work continuously, cutting multiple pieces with high precision and minimal supervision, further reducing costs and increasing efficiency.

Choosing Accurate Cutting Service for your CNC laser cutting needs ensures that you receive top-notch quality, precision, and customer satisfaction. Here’s why you should trust us with your CNC laser cutting projects:

We specialize in providing high-precision CNC laser cutting services. Our advanced machines guarantee that every cut is made with exact measurements, ensuring that even the most intricate designs are replicated with flawless accuracy. Whether it's for industrial or commercial use, we ensure that your specifications are met perfectly.

At Accurate Cutting Service, we offer flexibility in working with various materials, including metals (mild steel, carbon steel, aluminum, stainless steel), plastics, wood, acrylic, and more. This versatility allows us to handle a wide array of projects, from complex metal parts to delicate engraving on wood or plastic.

We use the latest CNC laser cutting technology, which provides faster processing times, smoother cuts, and cleaner results. Our modern fiber laser machines enhance cutting speed, while minimizing material waste and improving overall efficiency.

We understand that every project is unique, and we provide tailored solutions to meet your specific needs. Whether you require precision cutting for industrial parts, custom engraving, or decorative designs, we work closely with you to ensure the final product meets your exact requirements.

We are committed to delivering timely results, ensuring that you meet your project deadlines without compromising on quality. Our efficient process allows us to complete orders quickly while maintaining high standards of precision.

With years of experience in the CNC laser cutting industry, our skilled team ensures that each project is handled with expertise and care. We are equipped to tackle projects of all sizes, from small custom jobs to large-scale industrial applications.

By utilizing CNC laser cutting, we minimize material waste and reduce labor costs, making our services both cost-effective and environmentally friendly. This translates into savings for you, without sacrificing quality or efficiency.

At Accurate Cutting Service, quality is our top priority. We use strict quality control procedures to ensure that every cut is perfect and that all projects meet the highest industry standards. From initial consultation to final product delivery, we ensure complete satisfaction with every order.

We take pride in offering personalized service and building strong relationships with our clients. Our team is always ready to provide guidance, answer your questions, and assist with any design challenges you may face.

We offer competitive pricing for high-quality CNC laser cutting services, making it easy for you to get the best value for your investment. Whether you're working on a small custom job or a large commercial project, you’ll find our pricing to be reasonable and transparent. By choosing Accurate Cutting Service, you're partnering with a reliable, professional team that is dedicated to providing top-tier CNC laser cutting services tailored to your exact needs. Let us help you bring your projects to life with precision, speed, and exceptional quality.

In conclusion, CNC Laser Cutting, also known as engraving, is an advanced and highly effective technology for precision cutting, engraving, and marking across a wide range of materials. At Accurate Cutting Service, we leverage the latest CNC laser cutting technology to deliver exceptional results for both industrial and commercial projects. Whether it’s for manufacturing parts, intricate engravings, or custom designs, our commitment to precision, efficiency, and quality ensures that your needs are met with the highest standards.

We understand the importance of accuracy and fast turnaround times, which is why we provide tailored solutions for each project, working closely with our clients to meet their specific requirements. With our expertise, cutting-edge technology, and a customer-centric approach, we are proud to be a trusted partner for all your laser cutting needs.

Our versatile services, including the ability to work with various materials and deliver highly detailed cuts, make us the ideal choice for both large-scale industrial applications and smaller, custom projects. At Accurate Cutting Service, we are dedicated to providing cost-effective, high-quality laser cutting solutions, ensuring that you get the best value for your investment.

Partner with us today and experience the precision, reliability, and excellence that comes with every CNC laser cutting project we undertake.

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.