Fab 12, 2025 |

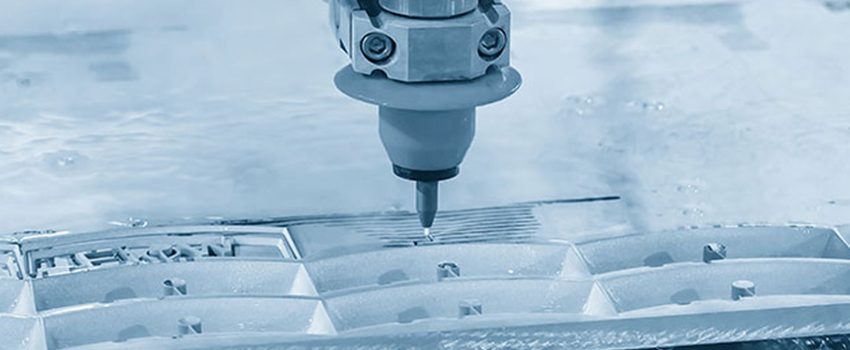

Waterjet Cutting Machine

Welcome to Accurate Cutting Service, your trusted partner for cutting solutions in industrial and commercial projects. We specialize in providing high-quality cutting services that meet the needs of a wide range of industries. Our advanced technology, including state-of-the-art waterjet cutting machine, ensures precise and efficient results for even the most complex projects.

Our waterjet cutting service is the ideal solution for projects requiring cold cutting processes, meaning there's no heat generated during the operation, preventing any heat-affected zones or distortion in materials. This makes it especially suitable for cutting sensitive materials such as metals, composites, glass, and plastics, providing clean, accurate cuts without altering their properties.

Not only is waterjet cutting highly effective, but it's also an environmentally friendly choice. The process uses high-pressure water mixed with abrasives to achieve precise cuts, reducing waste and minimizing the environmental impact compared to other cutting methods. At Accurate Cutting Service, we are committed to sustainability, ensuring our operations align with eco-friendly practices while delivering top-tier results.

Waterjet cutting is a precise and versatile cutting process that uses high-pressure water to cut through a wide range of materials, including metals, plastics, glass, ceramics, and stone. The process involves three key components: the water, the pressure system, and the cutting nozzle.

The process begins by pressurizing water to extreme levels, typically between 30,000 and 90,000 PSI (pounds per square inch), using a specialized pump. This high pressure enables the water to cut through even the toughest materials with incredible accuracy.

For tougher materials like metal or stone, abrasive particles such as garnet are added to the water stream. This abrasive mixture helps enhance the cutting power of the water, ensuring clean and precise cuts.

The pressurized water, often mixed with abrasives, is directed through a small, specialized nozzle. As the water exits the nozzle at extremely high velocity, it is capable of slicing through materials with pinpoint accuracy. The nozzle is typically moved along a pre-programmed path, which is controlled by a computer numerical control (CNC) system to achieve the desired shape or design.

One of the primary benefits of waterjet cutting is that it is a cold cutting process. This means there’s no heat involved, eliminating the risk of heat distortion or material warping, making it ideal for materials that are sensitive to temperature changes.

A Multi-Cutting Head Waterjet Cutting Machine is a highly advanced and Multifunctional industrial Equipment used in various industries for Systematic cutting of different materials. It utilizes high-pressure water mixed with an abrasive substance to cut through materials such as metal, stone, glass, ceramics, plastics, and composites. The key feature of this Multi Cutting Head Waterjet Cutting Machine is its ability to operate with multiple cutting heads, which allows for simultaneous cutting of several parts, significantly increasing productivity and reducing operational time.

A CNC Waterjet Cutting Machine is an Adaptable tool used in various manufacturing industries for cutting a wide range of materials. CNC stands for Computer Numerical Control, which means the machine is controlled by a computer program to carry out highly accurate cuts. The waterjet cutting process uses a high-pressure stream of water, sometimes mixed with abrasive materials like garnet, to slice through materials. This method is highly effective for cutting metals, ceramics, glass, plastics, stone, and composites.

An Abrasive Waterjet Cutting Machine is a specific type of waterjet cutting system that combines the high-pressure waterjet stream with abrasive materials to improve its cutting power. While a standard waterjet cutting machine uses only water to cut through materials, the abrasive waterjet includes finely ground abrasive particles, such as garnet, that are mixed with the water stream. This combination allows the machine to cut through harder and tougher materials that would otherwise be difficult to cut using pure water alone.

A Gantry Type Waterjet Cutting Machine is a sophisticated cutting tool used in industries requiring high precision and the ability to cut through various materials. The primary feature of this machine is its gantry system, which acts as a bridge structure that supports the cutting head and ensures accurate movement in all three axes—X, Y, and Z.

A Standard Abrasive Waterjet Cutting Machine is a type of waterjet cutting system that uses a combination of high-pressure water and abrasive materials to cut through a wide range of materials. The "abrasive" component, typically garnet, is mixed with water to create a powerful cutting stream capable of slicing through hard and tough materials, such as metals, ceramics, stone, glass, and composites.

Waterjet cutting technology offers numerous advantages, making it a popular choice across various industries. Here are some key benefits of using waterjet cutting machines:

Waterjet Systems provide extremely high precision and accuracy, capable of cutting intricate shapes and fine details. The ability to achieve tight tolerances makes them ideal for applications requiring detailed work, such as aerospace, automotive, and electronics.

Unlike traditional cutting methods that involve heat, waterjet cutting is a cold cutting process. This means there is no heat-affected zone (HAZ), eliminating the risk of material warping, distortion, or changes in mechanical properties. It is especially valuable for cutting heat-sensitive materials like plastics, metals, and composites.

Waterjet cutting is highly versatile, capable of cutting a wide variety of materials, including metals, stone, glass, ceramics, plastics, rubber, and more. This makes it suitable for many industries, such as manufacturing, construction, and automotive, where multiple types of materials need to be processed.

The precision of waterjet cutting results in minimal material wastage. The narrow kerf (cut width) and the ability to nest parts efficiently allow for maximum material utilization, reducing overall production costs and material waste.

Waterjet cutting is an eco-friendly process. It uses water and abrasives without creating harmful emissions or pollutants. Additionally, the process doesn’t generate hazardous fumes or waste products, making it a safer, more sustainable alternative to traditional cutting methods.

Since waterjet cutting relies on water and abrasive materials rather than tools that physically contact the material, there is no tool wear or maintenance involved. This reduces operational downtime and ensures consistent, high-quality cuts throughout the cutting process.

Waterjet cutting can handle a wide range of material thicknesses, from thin sheets to thick, tough materials. Depending on the pressure and abrasives used, waterjets can cut through materials that are several inches thick, making them suitable for heavy-duty applications.

Waterjet cutting produces smooth, clean edges with little to no post-processing required. This reduces the need for secondary operations like grinding or polishing, saving time and labor costs.

Unlike other cutting technologies that require tool changes for different materials or cuts, waterjet cutting only requires changes in water pressure or abrasive material, making it a quicker, more cost-efficient process.

At Accurate Cutting Service, we stand out as the leading provider of waterjet cutting solutions for industrial and commercial projects. Here's why we are the best choice for your cutting needs:

We utilize state-of-the-art waterjet cutting machines that deliver unparalleled precision, efficiency, and versatility. Our equipment is capable of handling complex designs, intricate shapes, and tough materials, ensuring top-quality results every time.

With years of experience in the cutting industry, our team of skilled technicians understands the unique requirements of each project. We provide expert guidance and solutions, helping you achieve optimal outcomes, whether you're cutting metals, plastics, ceramics, or more.

Our waterjet cutting machines are designed for high precision, ensuring clean, accurate cuts with minimal waste. We pride ourselves on delivering exceptional quality and tight tolerances for every job, no matter how complex.

We prioritize sustainability and eco-friendly practices. Our waterjet cutting process is a cold cutting method that produces no harmful emissions, minimizing environmental impact and ensuring a safer work environment.

We understand that every project is unique. That's why we offer customized waterjet cutting services tailored to your specific needs, whether it’s for large-scale industrial projects or small commercial applications.

We value your time. Our efficient workflow ensures that your project is completed on schedule, with no compromise on quality. We are committed to meeting your deadlines and delivering the best results within the time frame you need.

At Accurate Cutting Service, we prioritize customer satisfaction. Our dedicated team is always available to answer questions, provide updates, and ensure that your experience with us is seamless and stress-free.

In conclusion, waterjet cutting machine offer a powerful and versatile solution for a wide range of industries, delivering precision, efficiency, and environmental sustainability. Whether you are working with metals, plastics, stone, or glass, waterjet cutting provides clean, accurate cuts without the risk of heat distortion or material damage. The ability to cut complex shapes and thick materials with minimal waste and no tool wear makes waterjet technology an excellent choice for both simple and highly intricate projects.

With its numerous benefits, including reduced environmental impact, minimal maintenance, and the capacity to handle a diverse range of materials, waterjet cutting stands as a top-tier option for industries seeking reliable and high-quality cutting solutions. Whether you are looking to enhance your manufacturing processes or tackle a unique commercial project, waterjet cutting offer the performance and flexibility to meet your needs.

Along with our cutting services, we also provide CNC Laser Welding and PVD Coating to improve the quality and accuracy of your projects. Whether you need expert welding or strong coating options, our team is ready to provide excellent results. For more details or to talk about your project, please contact us today.

Visit Our Webiste: https://www.acscutting.com/

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.