Fab 13, 2025 |

CNC Laser Cutting Services

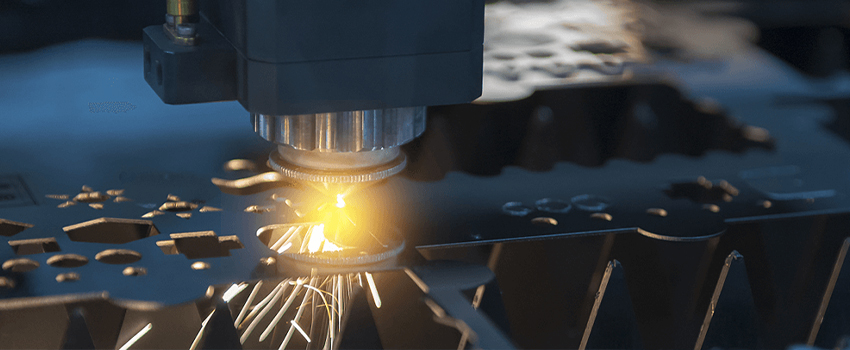

CNC laser cutting is a manufacturing process that uses a high-powered laser beam to precisely cut or engrave materials such as metal, plastic, wood, and ceramics. CNC stands for "Computer Numerical Control," which means that the laser cutting machine is controlled by a computer program. The machine follows exact instructions, ensuring high precision and consistency in every cut.

The process begins with a design file, often created using CAD (Computer-Aided Design) software, which is then converted into a code the CNC machine can understand. The laser cutting machine directs the laser beam to the surface of the material, where it either melts, burns, or vaporizes the material to create a clean, accurate cut. Depending on the material and thickness, different laser powers and cutting speeds are used.

One of the main advantages of CNC laser cutting is its ability to produce intricate and complex shapes with minimal waste. It’s also very precise, which is essential for industries such as aerospace, automotive, and electronics. Additionally, it requires little or no post-processing, which makes it an efficient option for mass production as well as custom one-off designs. The automation of the process also speeds up production times and reduces human error.

The cutting process of CNC laser cutting involves several steps, each crucial for achieving precise and clean cuts. Here's a breakdown of how it works:/p>

Before the cutting process begins, a design is created using CAD (Computer-Aided Design) software. This design is then converted into a machine-readable format, such as a DXF or SVG file. The design is imported into the CNC machine’s control software, which generates the necessary instructions (G-code) that guide the laser cutter’s movements.

Once the design is ready, the material (metal, wood, plastic, etc.) is placed onto the machine’s cutting bed. The material is typically secured by clamps or a vacuum system to prevent movement during cutting. The material must be aligned correctly, ensuring the laser cuts in the right locations.

Before starting, the laser beam is focused to the right intensity and diameter. The power and speed settings are adjusted based on the material type, thickness, and required cut quality. For instance, thicker materials require more power and slower speeds, while thinner materials may require less power and faster speeds.

Once everything is set, the laser cutting process begins. The CNC machine moves the laser head along the predefined path while the laser beam continuously fires at the material. The high-intensity laser beam melts, burns, or vaporizes the material at the cut line. As the laser moves, a nozzle blows gas (often nitrogen or oxygen) onto the cutting area to help remove debris and prevent oxidation, ensuring a clean cut.

After the cut is complete, the material is removed from the cutting bed. Depending on the application, further post-processing may be necessary, such as cleaning edges, deburring, or polishing.

Throughout this process, the CNC laser cutting system ensures high precision, repeatability, and minimal material waste, making it ideal for intricate and complex designs in industries such as aerospace, automotive, and electronics.

CNC laser cutting is a versatile and highly precise method used across various industries. By utilizing focused laser beams to cut or engrave materials, CNC laser cutting offers high-speed, accurate, and clean cuts. Here are some industries that use CNC laser cutting:

CNC laser cutting is used extensively in the automotive industry for cutting and shaping components like metal parts, body panels, and exhaust systems. The precision of laser cutting ensures that parts fit together accurately, which is crucial for the performance, safety, and aesthetics of vehicles.

Cutting of metal sheets for body parts

Cutting exhaust components

Manufacturing automotive molds and fixtures

In aerospace, precision is critical. CNC laser cutting is used for making parts that require tight tolerances, such as brackets, panels, and structural components. Laser cutting’s ability to cut through complex geometries makes it invaluable in this sector.

Cutting of thin metals used in aircraft frames

Producing heat shields, turbine components, and other precision parts

Engraving and etching serial numbers and other identifying markings

CNC laser cutting is a common process in manufacturing industries where high precision and efficiency are required. The ability to cut metals, plastics, and composites makes laser cutting useful for producing parts used in machines and industrial equipment.

Cutting sheet metal for machinery parts

Creating components for industrial tools, equipment, and packaging

Prototype development

The electronics industry benefits from CNC laser cutting for its ability to cut precise, intricate designs in thin metals or plastics used in various electronic components. This is especially important for manufacturing connectors, circuit boards, and housings for electronic devices.

Cutting and engraving of PCB (printed circuit boards)

Creating metal enclosures for electronic devices

Producing parts for consumer electronics like smartphones and laptops

In the jewelry industry, CNC laser cutting allows for the creation of intricate designs with high precision. It’s particularly useful for cutting precious metals like gold, silver, and platinum to create complex shapes, engravings, and textures.

Laser cutting of jewelry designs and engravings

Production of custom-made or bespoke jewelry

Marking gemstones with serial numbers or branding

Laser cutting is used to create decorative and structural elements in architecture and construction. CNC laser machine can cut through various materials like steel, wood, acrylic, and glass, enabling architects and designers to create detailed, customized elements for buildings and interiors.

Cutting of decorative metal panels and facades

Creating intricate window and door designs

Manufacturing custom signage and architectural details

The signage industry benefits greatly from CNC laser cutting for creating precise and detailed signs, both for indoor and outdoor use. Whether it’s a large-scale billboard, shop signs, or detailed interior signs, laser cutting provides the versatility to work with various materials.

Cutting and engraving acrylic, wood, and metal signs

Producing illuminated signs and displays

Custom logos and branding for businesses

Laser cutting allows for the creation of intricate designs in wood, metal, and other materials used in furniture production. The ability to cut precise patterns allows for detailed designs in everything from chairs to cabinetry.

Cutting decorative patterns in wood or metal panels

Creating custom designs for furniture

Engraving logos or details on furniture surfaces

While CNC laser cutting is primarily known for cutting hard materials, it is also used in the textile industry to cut fabrics with high precision. Laser cutting can cut through various fabrics like cotton, leather, and synthetic materials, making it ideal for fashion, upholstery, and fabric-based products.

Cutting intricate patterns for fashion designs

Engraving on textiles or leather products

Custom textile applications for home decor

CNC laser cutting plays a critical role in the medical field for manufacturing medical devices, implants, and surgical instruments. The precision and cleanliness of laser cutting ensure that parts meet strict medical standards.

Cutting precision medical instruments and implants

Engraving labels and identification marks on medical devices

Manufacturing custom prosthetics

Generally consumes less power, often operating at around 10 kW compared to other cutting methods.

We use the latest CNC laser cutting machine, which are capable of handling a wide variety of materials, including metals, plastics, wood, and more. Our equipment is continually upgraded to stay at the forefront of technological advancements, ensuring we can meet the most demanding project requirements.

Our team consists of highly skilled professionals with years of experience in CNC laser cutting. From design to execution, our technicians and engineers have the expertise to ensure your project is handled with care and precision. Whether it's a one-off custom piece or large-scale production runs, we can handle it all.

We understand that every project is unique. We offer tailor-made CNC laser cutting services to meet your specific requirements. Whether you need complex shapes, intricate engravings, or precise cuts, we work closely with you to bring your vision to life. Our flexibility allows us to tackle both small and large-scale projects with ease.

Time is crucial in most industries, and we pride ourselves on providing fast and efficient services without compromising on quality. Our CNC laser cutting process allows for quicker production times, ensuring you meet your deadlines while maintaining high-quality standards.

We offer competitive pricing without sacrificing quality. Our efficient laser cutting process minimizes material waste, which not only reduces costs but also contributes to more sustainable manufacturing practices. By choosing us, you get the best value for your investment.

We can work with a wide range of materials, including stainless steel, aluminum, acrylic, wood, carbon steel, and even some composites. Whether you need thin or thick material cutting, we have the tools and expertise to handle a variety of material types and thicknesses.

Our team works with cutting-edge software to ensure seamless design and cutting processes. We can accept various design formats, including CAD files, and offer expert support in creating or optimizing designs for laser cutting. This ensures that your project flows smoothly from conception to completion.

We stand behind the quality of our work. Each CNC laser cutting job undergoes rigorous quality control checks to ensure the final product meets or exceeds industry standards. Our commitment to excellence ensures that you receive flawless, high-quality results every time.

We prioritize customer satisfaction and go the extra mile to ensure that your needs are met. We work closely with you throughout the project, from initial consultation to delivery, offering expert guidance and support along the way. Our goal is to build long-term relationships based on trust, reliability, and mutual success.

We are committed to sustainability and reducing our environmental impact. Our CNC laser cutting process minimizes material waste and energy consumption, making it an eco-friendly choice for your manufacturing needs.

At Accurate Cutting Service, we are dedicated to providing top-tier CNC laser cutting services that cater to a wide range of industries and applications. With our cutting-edge technology, skilled team, and commitment to excellence, we ensure that every project is executed with precision, efficiency, and the highest quality standards. Whether you're working on a custom project, a large-scale production run, or need quick turnaround times, we are the trusted partner you can rely on. Let us help bring your ideas to life with accuracy and creativity.

Reach out today, and experience the difference of working with a CNC laser cutting service provider who puts your needs first!

We'd love to hear from you! If you have any questions, need a quote, or want to discuss your next CNC laser cutting project, don’t hesitate to get in touch. Our friendly and knowledgeable team is here to assist you every step of the way.

Phone: +91 9979228016

Email: acs.cutting@gmail.com

Address: 336/9, GIDC Industrial Estate Makarpura, Vadodara, Gujarat, India-390 010

Website: https://www.acscutting.com/

You can also fill out our online contact form or request a quote directly on our website for a fast response.

We look forward to partnering with you!

Along with our cutting services, we also provide CNC Laser Welding and PVD Coating to improve the quality and accuracy of your projects. Whether you need expert welding or strong coating options, our team is ready to provide excellent results. For more details or to talk about your project, please contact us today.

Visit Our Webiste: https://www.acscutting.com/

Cnc Pipe Laser Cutting, Pipe Laser Cutting, Cnc Laser Pipe Cutting, Laser Pipe Cutting, Cnc Water Jet Cutting, Hydro Jet Cutting, CNC Laser Cutting, CNC Laser Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.