Dec 07, 2023 |

Portable water jet cutting

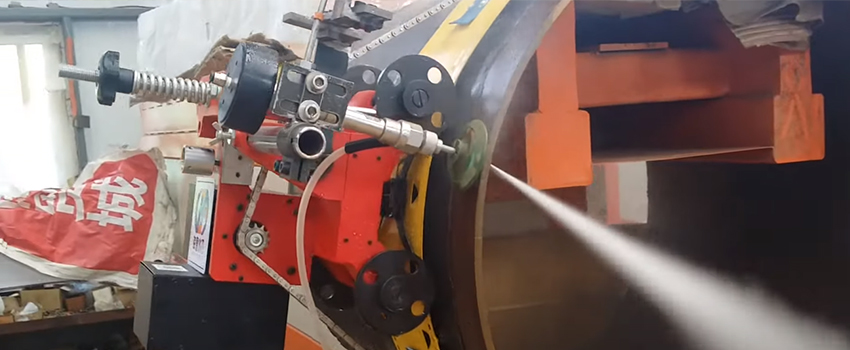

Portable water jet cutting has revolutionized manufacturing with its ability to slice through virtually any material with extreme precision using only a thin, high-pressure stream of water mixed with abrasive. Massive water jet machines that weigh tons have become standard equipment in machine shops and fabrication facilities. But hauling large workpieces across a factory to the cutting area reduces efficiency.

Furthermore, many industries require cutting and fabricating large structures on-site where it's impossible to bring such enormous cutting equipment. Portable water jet cutting technology solves these problems by packing robust pure water or abrasive jet cutting capabilities into compact, mobile units powered by electric or gas motors.

Portable water jet cutting Service provide water pressures up to 140,000 PSI supplied from a compact intensifier pump compatible with the available electrical power or engine output. The high-pressure water gets forced through an extremely narrow jewel orifice in the cutting head, generating a thin jet stream with enough kinetic energy to slice through metal, stone, glass, composites, rubber and many other materials. Introducing abrasive media like garnet sand into this jet stream enables portable units to cut virtually anything, even several inches of stainless-steel plate

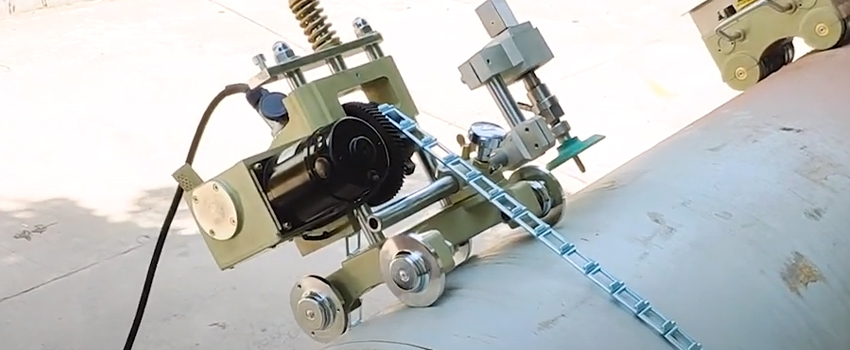

This intensified jet stream allows portable waterjet cutters to deliver similar cutting abilities to their much larger factory counterparts. But portable systems feature compact footprint designs less than 10 feet long and under 4 feet wide that are towable behind pickup trucks. Clever engineering fits the essential high-pressure components - intensifier pump, accumulator to maintain steady pressure, abrasive hopper, catcher tank, cutting head and controls - into a robust metal frame enclosed in sheet metal and sturdy polymer panels to create a durable, all-weather portable cutting station

The unique advantages of Portable water jet cutting - no heat distortion, extremely narrow kerf cuts, no contact forces, precision accuracy - make portable water jet cutters invaluable for field work in applications like:

In these and countless other on-site applications, portable water jet machines eliminate the major hassles and costs of moving heavy materials to stationary cutting centers or having technicians travel to remote locations with hand-held cutting tools unable to handle thick or large workpieces. Anyone trained to use these mobile water jets can bring immense cutting capabilities anywhere they're needed.

With so much robust cutting technology packed into compact mobile platforms, portable water jet cutters vary widely in capabilities and costs. Key factors to consider include:

Like their factory-based big brothers, portable water jet cutting systems require significant capital investment. But for companies regularly handling major fabrication and cutting work in the field, the exponential boost in on-site capabilities makes acquiring a portable water jet cutter one of the wisest equipment investments they could make.

Portable water jet cutting, Portable water jet cutting Service, Portable water jet cutting in Vadodara, Portable water jet cutting Service in Vadodara, Portable water jet cutting systems,

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.