Mar 03, 2025 |

Waterjet Cutting Machine

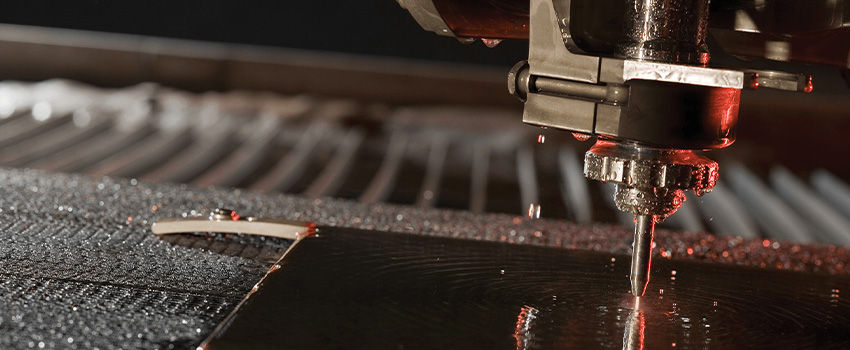

Welcome to Accurate Cutting, one of the largest cutting solution providers in Gujarat, India. With years of experience, we specialize in delivering precise cutting solutions across industries. Our most powerful tool is the Waterjet Cutting Machine, known for its exceptional accuracy and ability to cut a wide range of materials without distortion. This advanced technology is perfect for the engineering and manufacturing sectors, providing high-quality, intricate cuts that meet the highest standards. Let's Known About Types of Waterjet Cutting Machine.

The Multi-Cutting Head Waterjet Cutting Machine is an advanced Cutting Equipment of technology that significantly improve the capabilities of waterjet cutting processes. This innovative machine features multiple cutting heads, allowing for simultaneous cutting of multiple parts or intricate designs, which boosts productivity and reduces operational time. The use of several cutting heads also maximizes material utilization, as it allows for better organization of cuts, minimizing waste and improving efficiency.

One of the key advantages of a Multi-Cutting Head Waterjet Cutting Machine is its precision. Each cutting head operates independently with exceptional accuracy, ensuring that even the most intricate designs are cut with flawless precision. The machine utilizes a high-pressure stream of water, often mixed with abrasives, to cut through a wide variety of materials, including metals, stone, ceramics, glass, and composites. Unlike traditional cutting methods, waterjet cutting does not generate heat, preventing material warping or distortion, which is crucial for maintaining the integrity of the workpiece.

This technology is particularly beneficial in industries such as aerospace, automotive, manufacturing, and engineering, where complex shapes and high tolerances are often required. The ability to cut materials of different thicknesses and hardness, all while maintaining consistent quality, makes the Multi-Cutting Head Waterjet Cutting Machine indispensable for high-demand production environments.

Moreover, the multi-head feature allows for the optimization of machine uptime and reduces the need for multiple setups or machine switching, making it ideal for both small batch production and large-scale operations. With its superior cutting quality, speed, and efficiency, the Multi-Cutting Head Waterjet Cutting Machine has become a game-changer in modern manufacturing processes, offering businesses the ability to meet demanding requirements with ease and precision.

The CNC Waterjet Cutting Machine is a highly precise and versatile cutting solution widely used in industries that require intricate designs and high-quality cuts. CNC, which stands for Computer Numerical Control, allows for automation and precision control of the waterjet cutting process through computer programming. This machine utilizes a high-pressure stream of water mixed with abrasive material to cut through a variety of materials, including metals, plastics, glass, ceramics, and stone.

One of the main advantages of CNC Waterjet Cutting Machines is their ability to achieve intricate and complex shapes with extreme accuracy. The CNC system enables the operator to program precise cutting paths, ensuring that every cut is consistent, repeatable, and meets exact specifications. This makes it an ideal solution for industries such as aerospace, automotive, architecture, and manufacturing, where high tolerances and fine details are required.

Additionally, the CNC Waterjet Cutting Machine is capable of cutting materials of varying thicknesses without the risk of heat-affected zones or material distortion, which is a common issue with traditional cutting methods such as lasers or plasma cutting. This makes waterjet cutting a preferred option when dealing with sensitive or heat-sensitive materials.

The machine’s versatility is another key feature. It can cut a wide range of materials, from soft substances like rubber to harder materials such as titanium or granite, without the need for tooling changes or special setups. CNC Waterjet Cutting Machines are also capable of performing operations such as engraving, etching, and even beveled cuts, further enhancing their usefulness across various applications.

In summary, the CNC Waterjet Cutting Machine combines precision, versatility, and efficiency, making it an indispensable tool for modern manufacturing processes, offering businesses the ability to produce high-quality, intricate parts with minimal waste and fast turnaround times.

The Abrasive Waterjet Cutting Machine is a cutting-edge technology that combines the power of high-pressure water with abrasive materials to cut through a wide range of tough materials. Unlike pure waterjet cutting, which uses only water to cut softer materials, the abrasive waterjet system introduces an abrasive substance, typically garnet, into the high-pressure water stream. This creates a powerful, concentrated force that can easily slice through hard materials like metals, stone, ceramics, glass, composites, and more.

One of the primary advantages of the Abrasive Waterjet Cutting Machine is its ability to cut thick and tough materials with high precision. The machine’s waterjet stream, combined with abrasive particles, can cut through materials up to several inches thick, making it ideal for industries that deal with heavy-duty materials such as aerospace, automotive, and manufacturing. Additionally, this cutting method is not affected by the material's hardness, allowing it to cut virtually any material with ease.

The key benefit of abrasive waterjet cutting is its ability to produce smooth, clean cuts with no heat-affected zones (HAZ). Since waterjet cutting does not generate heat during the cutting process, it ensures that the material’s properties remain intact, preventing any warping, distortion, or material degradation. This is particularly crucial when cutting sensitive materials, such as metals and composites, which may be prone to heat damage with other cutting methods.

Abrasive waterjet cutting is also highly versatile, offering a wide range of applications including precision cutting, engraving, and etching. It is capable of producing intricate shapes and designs with minimal kerf width and no tool wear, leading to excellent repeatability and accuracy.

In summary, the Abrasive Waterjet Cutting Machine is an essential tool for industries requiring high-precision cuts through tough materials. Its ability to handle a wide variety of materials, produce clean cuts without heat distortion, and deliver high-quality results makes it a valuable asset in modern manufacturing and engineering processes.

The Gantry Type Waterjet Cutting Machine is a robust and highly efficient cutting solution that features a unique design to ensure precision and flexibility in cutting a wide range of materials. This type of machine is characterized by a gantry-style framework, where the cutting head is suspended and moves along two horizontal tracks, allowing for precise movement over large workpieces. The gantry design provides increased stability and support, making it ideal for cutting larger or heavier materials with high accuracy.

One of the key benefits of the Gantry Type Waterjet Cutting Machine is its ability to cut large sheets of material with exceptional precision. The gantry system allows for precise control over the cutting head, resulting in high-quality cuts without distortion or warping, which is especially important for industries that require intricate and detailed designs. The machine can cut through various materials, including metals, composites, glass, stone, and plastics, making it highly versatile and suitable for a wide range of applications in fields such as aerospace, automotive, manufacturing, and architecture.

The Gantry Type Waterjet Cutting Machine is also known for its ability to maintain consistent cutting quality over large areas, which is especially useful in high-volume production environments. The system can handle thick materials efficiently, and it can cut complex shapes and intricate designs without the need for specialized tools or tooling changes.

Additionally, this machine offers improved speed and efficiency compared to other waterjet cutting machines, due to its design that allows for faster movement across the work surface. The system can be easily programmed through CNC controls to handle automated cutting tasks, ensuring precision, repeatability, and minimal human intervention.

In conclusion, the Gantry Type Waterjet Cutting Machine is a powerful tool for industries that require high-precision cutting of large, complex parts. Its robust structure, accuracy, and versatility make it an excellent choice for a wide variety of demanding manufacturing applications.

The Standard Abrasive Waterjet Cutting Machine is a versatile and efficient cutting solution that utilizes high-pressure water mixed with abrasives, such as garnet, to cut through a variety of materials with exceptional precision. This type of machine is designed to handle standard cutting tasks in industries where accuracy, speed, and cost-efficiency are critical. The combination of water and abrasives creates a powerful cutting stream capable of slicing through materials ranging from metals and composites to stone and glass.

One of the main advantages of the Standard Abrasive Waterjet Cutting Machine is its ability to cut thick materials without heat distortion. Unlike traditional cutting methods such as laser or plasma cutting, which generate heat, the abrasive waterjet process does not alter the material's properties. This ensures that materials retain their integrity, making it ideal for heat-sensitive materials or components requiring tight tolerances.

The Standard Abrasive Waterjet Cutting Machine offers high-quality cuts with minimal kerf width, producing smooth, clean edges without burrs. It’s capable of cutting intricate and complex shapes with great precision, making it a preferred choice for industries like aerospace, automotive, and manufacturing. The machine also excels at cutting multiple materials simultaneously, increasing productivity and reducing waste.

Another significant benefit of this cutting method is its versatility. The Standard Abrasive Waterjet Cutting Machine can handle various material thicknesses, allowing it to be used in both small-scale and large-scale production environments. With its ability to cut metals, plastics, ceramics, rubber, and even some food materials, this machine is ideal for a wide range of industries and applications.

In summary, the Standard Abrasive Waterjet Cutting offers superior precision, versatility, and reliability. It is a valuable tool for businesses looking for an efficient cutting solution that maintains material integrity while delivering high-quality results in demanding production environments.

In conclusion, Accurate Cutting has established itself as a leading cutting solution provider in Gujarat, India, offering cutting-edge technology to meet the diverse needs of the engineering and manufacturing industries. With years of experience, we specialize in precision cutting with our powerful Waterjet Cutting Machines, delivering high-quality results without compromising the integrity of the materials.

The different types of Waterjet Cutting Machine, including the Multi-Cutting Head, CNC, Abrasive, Gantry Type, and Standard Abrasive models, each bring unique benefits to the table. These technologies offer precision, versatility, and efficiency, catering to industries that require intricate cuts, complex shapes, and the ability to work with a variety of materials.

Whether you are looking for high-speed cutting with multiple heads, intricate designs with CNC control, or robust performance with abrasive capabilities, our machines provide the ideal solutions to meet demanding requirements. With our advanced waterjet technology, businesses can achieve superior results, optimize productivity, and minimize waste while ensuring the material’s integrity is preserved.

At Accurate Cutting, we are committed to delivering reliable and innovative cutting services that align with industry standards, empowering your business to thrive in a competitive market. Partner with us for all your cutting needs, and experience the precision and expertise that come with years of dedication and cutting-edge technology.

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.