Jan 13, 2025 |

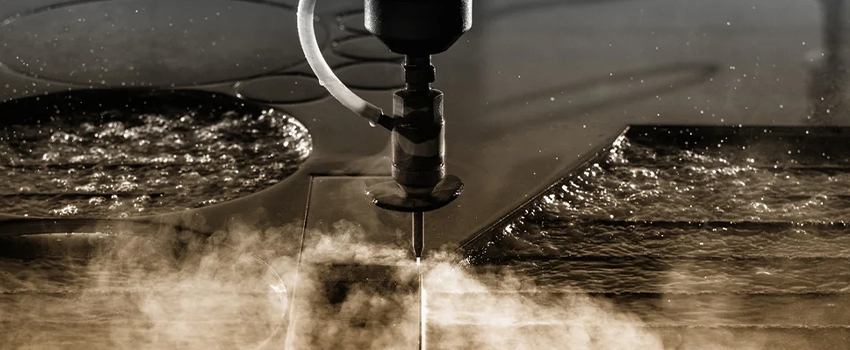

Waterjet Cutting Machine

Welcome to Accurate Cutting Services! We provide comprehensive cutting solutions for all industries, including the commercial sector. Specializing in highly rated waterjet cutting, its known for its unique cold cutting process, which ensures precision and versatility across a wide range of materials and applications. Waterjet cutting has emerged as one of the most advanced and versatile cutting technologies available today. It provides an innovative solution for industries that require precise cuts and intricate designs. In this comprehensive guide, we will discover everything you need to know about waterjet cutting, its benefits, and the industries it serves.

Waterjet cutting is a high-precision, cold cutting process that uses a high-pressure stream of water, often mixed with an abrasive material, to cut through a wide variety of materials. It is a non-thermal cutting process, meaning it does not produce heat-affected zones (HAZ), which helps preserve the integrity of the material being cut.

The process begins with water being pressurized to extremely high levels, often up to 60,000 PSI (pounds per square inch), and then forced through a small nozzle to create a fine, concentrated jet of water. This jet is capable of cutting through hard materials, such as metals, stone, glass, and ceramics, without the need for traditional heat-based methods like laser or plasma cutting.

In many cases, the waterjet stream is mixed with an abrasive, such as garnet, to increase cutting power. The combination of high-pressure water and abrasive materials allows for cutting through thicker and denser materials, providing versatility in the types of materials that can be processed.

Waterjet Cutting Machine offers the advantage of being able to produce complex, intricate designs with high precision. The process is commonly used for cutting flat sheets of materials but can also be adapted for 3D cutting in some systems. Unlike other cutting methods that rely on heat or mechanical force, waterjet cutting produces clean edges with minimal waste, making it an eco-friendly option for many applications.

Waterjet cutting machines consist of several components, including a high-pressure pump, a nozzle, and an abrasive delivery system. Here's a step-by-step explanation of how the process works:

1. High-Pressure Pump: The first step in waterjet cutting is pressurizing the water. The water is drawn from a reservoir and pumped through a high-pressure system where it reaches pressures of up to 60,000 PSI.

2. Nozzle: The pressurized water is then forced through a tiny nozzle, which directs the water into a highly focused stream. This stream is capable of cutting through various materials with incredible precision.

3. Abrasive Material (if used): In some applications, the waterjet cutting process uses an abrasive material, such as garnet, to increase the cutting power. The abrasive is mixed with the water stream to help cut through denser or tougher materials.

4. Cutting the Material: The concentrated water jet is directed at the material to be cut, creating a high-velocity impact that erodes the material, creating a clean and precise cut.

5. Control Systems: Modern waterjet cutting machines use computer numerical control (CNC) systems, which enable operators to program the exact shape, size, and positioning of cuts, ensuring high accuracy and consistency.

Waterjet cutting is used across a wide range of industries due to its precision, versatility, and ability to handle a variety of materials. Some of the most prominent industries that benefit from waterjet cutting include:

The aerospace industry requires materials to be cut with extreme precision, as even small variations can lead to significant performance issues. Waterjet Solutions are widely used in aerospace manufacturing for cutting materials such as titanium, aluminum, and composites used in aircraft components. Its ability to cut complex shapes and intricate details without generating heat makes it ideal for applications like turbine blade production, fuselage sections, and wing components.

The automotive industry relies heavily on waterjet cutting for manufacturing high-quality components that meet stringent safety and performance standards. Waterjet cutting is used to cut materials such as metals, plastics, and rubber for parts like brake pads, body panels, and engine components. Its precision ensures that components are made to the exact specifications required for assembly.

Metal fabrication is one of the primary industries that benefits from Advanced Waterjet Technology. Waterjet cutting machines can cut a wide variety of metals, including steel, aluminum, brass, and copper, into intricate shapes and designs. The ability to cut through thick metals without warping or distorting the material makes waterjet cutting ideal for applications like creating machinery parts, structural beams, and custom metal components.

Waterjet cutting is an excellent solution for cutting stone and marble, which are often used in countertops, flooring, and decorative features. Stone cutting requires a high level of precision to achieve clean, smooth edges and intricate patterns. The waterjet process can create detailed designs in stone, such as custom inlays, mosaics, and engraved patterns, with minimal waste and no heat damage.

Waterjet cutting is commonly used in the glass industry to create intricate glass designs, including windows, mirrors, and decorative glass panels. Glass is a delicate material, and traditional cutting methods can cause cracking or chipping. Waterjet cutting, on the other hand, offers a smooth, precise cut with no heat, preventing the risk of damage.

Waterjet cutting has applications in the food industry, particularly in cutting soft materials like meats, dough, fruits, and vegetables. The process ensures that the materials are cut cleanly and without contamination. It is often used for food packaging and portion control, as well as slicing delicate food items into uniform pieces.

In general manufacturing and industrial design, waterjet cutting is used for creating prototypes, cutting machine components, and producing customized parts for various applications. Its ability to cut a variety of materials with precision makes it an essential tool in many different fields, from creating industrial tools to producing custom-made products for consumer markets.

Waterjet cutting Machine is also utilized in architecture and construction, particularly for creating custom features in building facades, interiors, and structural elements. It is used to cut materials such as metal, glass, and stone, allowing architects and designers to bring their creative visions to life with high precision.

Waterjet cutting offers numerous advantages over traditional cutting methods. Some of the key benefits of waterjet cutting include:

Advanced Waterjet Technology provides high precision with minimal tolerance. The process is capable of cutting complex and intricate shapes with excellent accuracy, making it ideal for applications that require tight tolerances and detailed designs.

Unlike laser, plasma, or oxy-fuel cutting, Waterjet Systems is a cold cutting process. This means there is no heat generated during the cutting process, which eliminates the risk of heat-affected zones (HAZ). This is particularly important when working with materials that are sensitive to heat, such as metals, plastics, and composites.

Waterjet cutting can be used on a wide range of materials, including metals, plastics, ceramics, glass, composites, rubber, and even food. This versatility makes it an excellent choice for industries that need to work with different types of materials in their manufacturing processes.

In traditional cutting methods, different tools are often required to cut different materials or shapes. With Waterjet Cutting Machine, there is no need to change tools, as the same nozzle can be used for a variety of materials, reducing downtime and increasing productivity.

Waterjet Machine is known for its high efficiency, which helps minimize material waste. The narrow kerf (cut width) produced by the waterjet results in less scrap material, making it an environmentally friendly and cost-effective option for manufacturing.

Waterjet cutting produces smooth, clean edges with little to no burrs or roughness. This reduces the need for additional finishing work, saving time and money in the production process.

Since waterjet cutting uses water as the primary cutting medium and does not rely on harmful chemicals or gases, it is considered an environmentally friendly cutting method. Additionally, the water used in the process can often be recycled, further reducing its environmental impact.

Waterjet cutting can easily cut through thick materials, sometimes up to several inches in thickness, depending on the material and the machine’s capabilities. This makes it an excellent option for industries that require cutting through heavy-duty materials, such as metals and stone.

At Accurate Cutting Services, we pride ourselves on offering top-quality Water Jet Cutting Service that meet the needs of a wide range of industries. Here’s why we are the best choice for your waterjet cutting needs:

We use the latest waterjet cutting technology to ensure precision, efficiency, and quality in every project. Our machines are equipped with advanced CNC systems that allow for highly accurate cuts and detailed designs, ensuring that your products meet the highest standards.

Our team of experts has years of experience in Waterjet Systems and understands the unique requirements of different industries. We work closely with you to understand your needs and provide customized cutting solutions that deliver the best results.

We only use the highest quality materials for our waterjet cutting projects. Whether you’re working with metal, glass, stone, or any other material, we ensure that the cutting process is done with the utmost care to maintain the integrity of the material.

We offer competitive pricing without compromising on quality. Our efficient processes help reduce waste, save time, and provide cost-effective solutions for your cutting needs, allowing you to get the best value for your investment.

We understand the importance of meeting deadlines in the manufacturing world. Our Water Jet Cutting Service is designed to provide fast turnaround times, ensuring that your products are delivered on schedule.

Customer satisfaction is our top priority. We go the extra mile to ensure that our clients are happy with the results, and we work closely with you throughout the process to ensure your specific requirements are met.

Water Jet Application is an advanced, versatile, and precise cutting method that has revolutionized manufacturing across multiple industries. Its ability to cut through a wide range of materials with minimal waste and no heat-affected zones makes it an ideal solution for applications that require high precision and quality. From aerospace and automotive to food processing and architecture, waterjet cutting is transforming the way products are designed and manufactured.

With its many benefits, including cost-effectiveness, environmental friendliness, and versatility, waterjet cutting is becoming the go-to solution for businesses that need reliable, accurate, and efficient cutting services. At [Your Company Name], we offer industry-leading waterjet cutting services that deliver exceptional results for every project.

We offer a wide range of services tailored to meet the unique needs of different industries. Contact us today to discuss your project, request a quote, or learn more about how our Advanced Waterjet Technology can benefit your business.

If you're ready to explore the benefits of waterjet cutting for your business or project, contact us today! Our team of experts is here to answer any questions you have and provide customized solutions tailored to your needs.

Let us help you achieve precision, efficiency, and quality in your cutting projects with our waterjet cutting services. Get in touch with us now!

Accurate Cutting Services is one of the most reputable names in CNC Laser Cutting & Other Cutting Services. Our expert team works with utmost professionalism, and we have successfully completed numerous projects across India and in several other countries such as Kenya, Nigeria, Nairobi, and many more.

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.