Jan 03, 2025 |

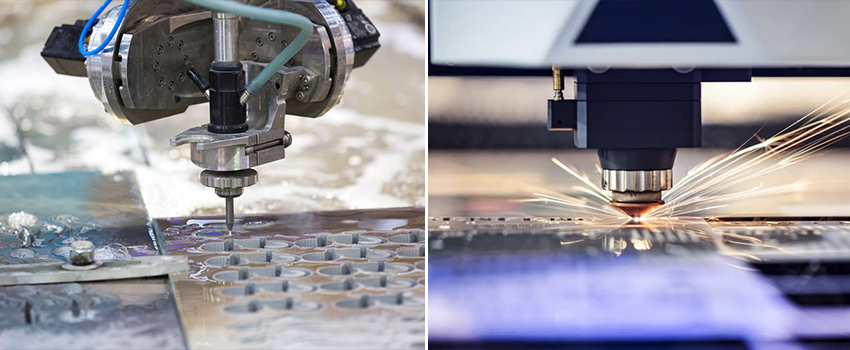

Waterjet Cutting Machine

Welcome to Accurate Cutting Services! We are your trusted partner for precision cutting solutions, offering Progressive Waterjet Cutting and CNC Laser Cutting for all types of industries. With advanced technology and expert craftsmanship, we provide cutting-edge solutions to meet the diverse needs of industries like aerospace, automotive, architecture, manufacturing, and more. We specialize in providing the best cutting services in Gujarat and other states of India.

Our Waterjet Cutting Machine delivers exceptional accuracy without heat distortion, making them suitable for cutting a wide range of materials, from metals to stone and plastics. Meanwhile, our CNC laser cutting machine offer unmatched precision and speed, delivering clean, precise cuts with minimal material waste.

At Accurate Cutting Services, we are committed to delivering high-quality results, on-time delivery, and customer satisfaction. Whether you need intricate designs, prototypes, or large-scale production runs, we have the expertise and tools to bring your projects to life with exceptional precision. Trust us for all your cutting needs – we make accuracy our priority!

Waterjet Cutting Process uses a high-pressure stream of water to cut through materials. To improve the cutting power, abrasive materials like garnet are often added to the waterjet stream. It is also famous as the Cold Cutting Process. The waterjet cutting process is capable of cutting a wide range of materials, including metals, plastics, ceramics, glass, stone, and composites, with exceptional precision and minimal heat distortion.

The Waterjet Systems operates by forcing water at extremely high pressures (up to 60,000 psi) through a tiny nozzle, which directs the water stream onto the material to be cut. The addition of abrasive particles to the waterjet stream allows it to cut through even the toughest materials, making it suitable for a variety of industries, from aerospace to architecture.

One of the main advantages of waterjet cutting is that it does not produce heat, meaning there is no heat-affected zone (HAZ) that can warp or distort the material. This makes waterjet cutting an ideal solution for materials that are sensitive to heat or require precise cuts.

Waterjet Cutting Machine can cut through virtually any material, whether it is soft or hard, thin or thick. This versatility allows businesses to use a single machine for various applications.

Waterjet cutting offers exceptional precision, with the ability to cut intricate shapes and designs with tolerances as tight as ±0.003 inches (0.076mm). This precision is vital in industries such as aerospace and medical device manufacturing.

Waterjet Solutions is an environmentally friendly process as it uses water and abrasives without producing harmful fumes or gases. The process generates minimal waste, and the water can be recycled and reused.

Unlike traditional cutting methods that require specialized tooling, waterjet cutting is a flexible and cost-effective option. The machine's nozzle can be easily adjusted to accommodate different shapes and sizes without needing custom tools or fixtures.

Waterjet Cutting Machine can handle materials up to 12 inches thick, making it a powerful tool for industries that require cutting large or thick materials.

Advanced Waterjet Technology finds applications in a wide range of industries. Some of the most common industries benefiting from waterjet cutting include:

Waterjet cutting is used to cut lightweight yet durable materials such as aluminum, titanium, and composites in the aerospace industry.

Waterjet cutting services are widely used for producing automotive parts, including engine components, body panels, and trim pieces.

Waterjet cutting can be used to cut stone, glass, and ceramic tiles, as well as architectural designs and sculptures.

Waterjet cutting allows for the fast and accurate cutting of prototypes and end-use parts in manufacturing.

The food industry uses Waterjet Systems for cutting dough, meat, and vegetables with high precision and hygiene standards.

Waterjet Cutting Machine can handle materials up to 12 inches thick, making it a powerful tool for industries that require cutting large or thick materials.

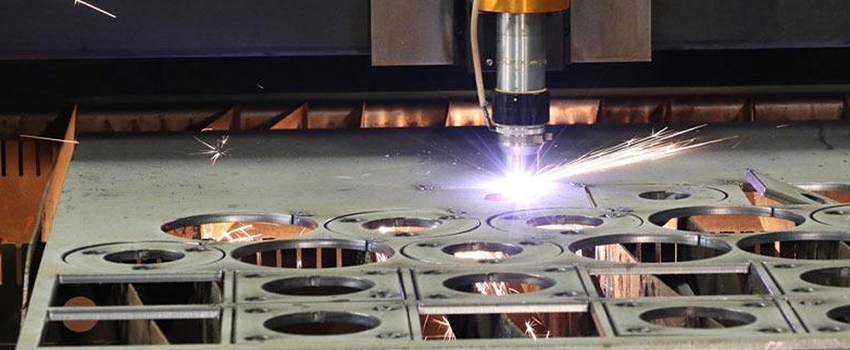

CNC Laser Cutting is a highly advanced cutting process that uses a focused laser beam to cut or engrave materials with high precision. The CNC (Computer Numerical Control) aspect of the machine allows for automated control of the laser, making it possible to produce complex cuts and designs quickly and accurately.

CNC laser cutting machine works by focusing a high-powered laser beam onto the material's surface. The intense heat from the laser melts or vaporizes the material, creating a clean and precise cut. The process is further enhanced by using a gas (usually oxygen or nitrogen) to blow away the molten material and create a smooth edge.

CNC Laser Cutting Services offer excellent precision with a high level of accuracy, often within 0.001 inches. This makes them ideal for cutting intricate patterns and designs in both small and large production runs.

CNC laser cutting machine is faster than many traditional cutting methods. The CNC automation allows for continuous, high-speed cutting, which results in higher productivity and reduced operational costs.

CNC Laser Cutting is an efficient process that results in minimal material waste. The narrow laser beam ensures that only the material being cut is affected, reducing the need for excess material.

The high precision and clean edges produced by CNC Laser Cutting typically require little or no post-processing, which saves time and resources.

CNC laser cutting machine can be used to cut a variety of materials, including metals (stainless steel, aluminum, copper, etc.), plastics, wood, and even fabrics. It is highly versatile and can be adapted to different materials based on the needs of the project.

Since laser cutting does not rely on physical contact with the material, there is no wear and tear on tools, leading to reduced maintenance costs and longer machine life.

CNC Laser Cutting Services produces smooth and polished edges without burrs or rough finishes, which is ideal for parts that require high-quality finishes.

CNC laser cutting is widely used across various industries. Here are some of the main applications:

CNC Laser Cutting Machine is extensively used in the metal industry to cut sheet metal, structural steel, and metal components used in machinery and vehicles.

Laser cutting allows for the production of intricate signs, logos, and displays with high detail and precision.

Laser cutting is commonly used to cut components and parts for electronics, electrical devices, and circuit boards.

CNC Laser Cutting empowers the creation of detailed jewelry pieces as well as cutting and engraving on leather, fabric, and other materials for fashion accessories.

CNC laser cutting machine is used to cut medical instruments, implants, and other precise components in the medical industry.

Artists and designers use CNC laser cutting for creating intricate patterns and designs on various materials, from wood to acrylic.

As a leading provider of waterjet cutting and CNC Laser Cutting Services in Gujarat, India, we offer Cutting-edge technology, unmatched expertise, and a commitment to delivering superior results. Here are the key reasons why our clients choose us for their precision cutting needs:

We utilize the latest waterjet cutting and CNC laser cutting machine equipped with the most advanced features to deliver precise and efficient cutting solutions.

Our team of skilled professionals has years of experience in the industry, ensuring that every project is handled with expertise and care. We provide customized solutions tailored to meet the specific needs of our clients.

We are committed to delivering the highest quality results, with a focus on precision, accuracy, and exceptional finishes. Our cutting machines are designed to handle a variety of materials with the utmost precision.

We understand the importance of time in business operations. We pride ourselves on our ability to deliver projects within the stipulated time frame, ensuring minimal downtime and maximum productivity for our clients.

As a leading cutting services provider, we offer competitive pricing without compromising on the quality of our services. Our goal is to provide affordable cutting solutions that meet the budgets of our clients.

We cater to a wide range of industries, including aerospace, automotive, manufacturing, architecture, and more. Whether you need precision parts or intricate designs, we have the expertise and tools to deliver.

We value our clients and prioritize their needs. Our customer-centric approach ensures that we understand the requirements of each project and provide solutions that exceed expectations.

Environmental Responsibility: We are committed to environmentally friendly practices, from the efficient use of resources to minimizing waste and recycling wherever possible.

Waterjet cutting services and CNC Laser Cutting Services are two of the most powerful and versatile Services in modern manufacturing or industrires. Their precision, speed, and ability to cut a wide range of materials make them invaluable assets to industries around the world. As the leading service provider of waterjet cutting and CNC laser cutting machine in Gujarat, India, we pride ourselves on offering top-quality cutting solutions for diverse applications. With advanced technology, skilled professionals, and a customer-focused approach, we are your trusted partner for all your cutting needs. Whether you require intricate designs, prototypes, or large-scale production, we are here to deliver exceptional results every time.

Waterjet Cutting Machine, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Machine Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Machine Solutions, Waterjet Machines, Waterjet Solutions, Abrasive Waterjet, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting Machine, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Machine Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.